161

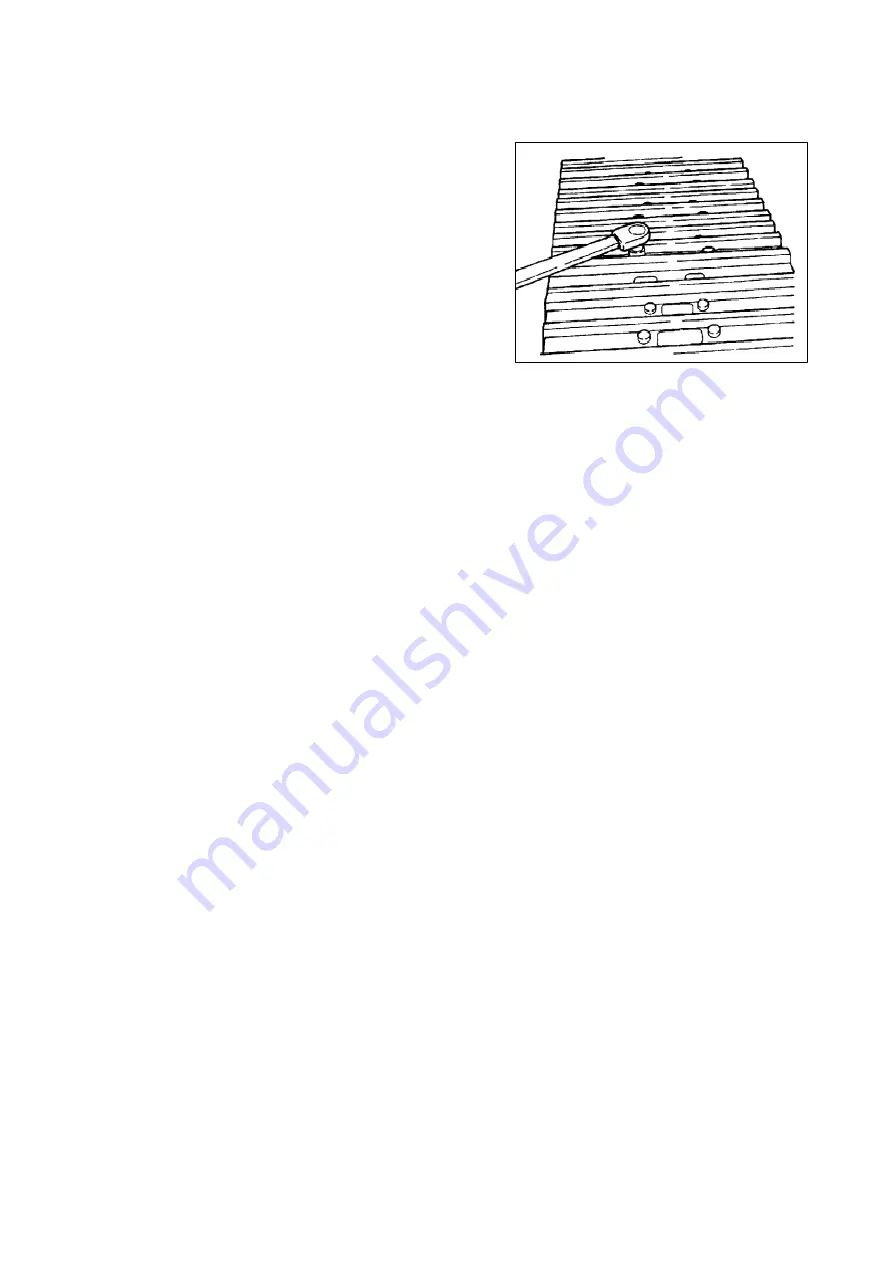

4.5.3.3 Check and fasten track bolt.

If operating machine with bolts loosened,

there is hazard that the bolts will rupture. Therefore

the loosened bolts should be fastened.

Tightening method

Track shoe

1)

Tighten at torque 490 ± 49 N m (50 ± 5 kgf m,

360 ± 36 lbft), then check to make sure that

nuts contact with track link surfaces securely.

2)

After checking, retighten 120° ± 10°.

Rubber block ( if mounted)

1)

Tighten at torque: 549 ± 59 N m (56 ± 6 kgf

m, 405 ± 43 lbft).

2)

After tightening, check to ensure that nut and

track link contact surface contact against each

other securely. .

Tighten sequence

Tighten bolts in the sequence given in right

fig.

With bolts tightened, check bolts and track

link mating face to ensure they contact

securely.

Summary of Contents for SWE150F

Page 19: ...12 18 No unauthorized access label Warning Stay clear of operation area of working device...

Page 22: ...15 23 Gravity label 24 Hydraulic oil label 25 Greasing...

Page 151: ...144 4 4 9 Hose...

Page 193: ...186 5 Technical specification...

Page 197: ...190 5 1 4 Circuit diagram...

Page 199: ...192 5 1 6 Hydraulic diagram...

Page 204: ...197 5 2 4 SWE210F Circuit diagram...

Page 206: ...199 5 2 6 Hydraulic diagram...