47

(3)Check connecting rod

If connecting rod bending, twisting or big end shaft bush and small end outer ring movement or

crack on one side, should be rejected and replaced with new one.

a) Check small end diameter

If out of the standard or exceed service limit, replace the connecting rod.

b) Check big end diameter

If out of the standard or exceed service limit, replace the connecting rod.

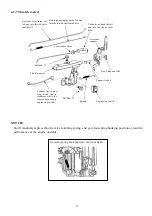

c) Connecting rod big end oil clearance

・

Wipe oil off the crank pin and connecting rod bearing mating surface.

・

Set the plastic gauge on the crank pin, connecting rod and bolt to specified torque.

:

Torque 13±1N.m

NOTICE: Place the plastic gauge axially.

・

Remove connecting rod and measure with plastic gauge.

・

If the clearance exceeds the service limit, replace the connecting rod and recheck the clearance.

(4) Camshaft check

The camshaft is main driving part of the train valve mechanism, which controls the intake and exhaust

valves opening and closing.

Feature: The shaft is equipped with cam and journal which can control intake and exhaust. When

operating, camshaft operating face and lifter will be badly rubbed from periodically impacting and

easily be damaged.

So, the camshaft shall be wearable and lubrication well.

Standard

Service limit

16.005-16.021mm

16.090mm

Standard

Service limit

30.000-30.018mm

30.066mm

Standard

Service limit

0.019-0.049mm

0.120mm

Plastic feeler with scale

Plastic feeler

Bolt

Summary of Contents for EA190V

Page 1: ...EA190V SERVICE MANUAL...

Page 2: ......

Page 8: ...8 II DIMENSION AND TORQUE 2 1 Engine dimension 2 1 1 Appearance dimension...

Page 9: ...9 2 1 2 Installation hole position 2 1 3 P T O dimension figure Engine Mounting Face...

Page 49: ...49 4 4 Electric diagram Engine switch Engine switch Spark plug Ignition coil Black OFF ON...

Page 50: ......

Page 51: ......