45

e

:

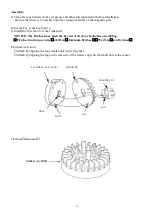

) Oil seal

・

Apply oil to the circumference of a oil seal.

・

Drive the oil seal in the cylinder barrel using following tool.

:

Tools Driver handle, Retainer assembler

・

Apply the lubrication oil on, after reassembling.

f)

:

Piston

・

Apply oil to the piston and cylinder

・

Install the piston with the mark on the piston head toward the

f

lywheel side.

(corrected 2018.1.20)

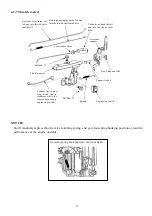

(2) Piston check

Check the piston and cylinder for contacting, and check the groove for defects, piston top for burn and

cracks. If damaged, replace.

Clean the carbon deposit

Clean the deposit round the piston top and cylinder neck before checking, first soak the carbon

deposit with kerosene, and then clean with meter scraper or metal brush.

a) Piston skirt O.D

Measure the piston skirt O.D with outside micrometer,

if out of the service limit, replace it.

Standard

Service limit

67.989-67.971mm

67.850mm

b) Piston pin bore to piston clearance

Separately measure the piston pin bore I.D and O.D with inside micrometer and outside micrometer.

Then calculate clearance by measuring results.

Standard

Service limit

0.004-0.016

0.060

10mm

Piston ring compressor

commercial available

Driver handle

Retainer assembler

Oil seal

Summary of Contents for EA190V

Page 1: ...EA190V SERVICE MANUAL...

Page 2: ......

Page 8: ...8 II DIMENSION AND TORQUE 2 1 Engine dimension 2 1 1 Appearance dimension...

Page 9: ...9 2 1 2 Installation hole position 2 1 3 P T O dimension figure Engine Mounting Face...

Page 49: ...49 4 4 Electric diagram Engine switch Engine switch Spark plug Ignition coil Black OFF ON...

Page 50: ......

Page 51: ......