26

4-2 Preparation of servicing

4-2-1 Safety precautions

WARNING

:

Indicate a possibility of invalid warranty and personal or equipment damage if instructions are

not followed.

Please pay special attention to the following:

1) Strictly set the engine according to the regulated power on the nameplate. Do not overload, overrun

the engine or run it with low load and at low speed in a long time.

2) Use regulated brand of gas and fuel. The fuel should be fully deposited and filtrated before use. Keep

clean the fuel filler, change the oil periodically.

3) Periodically check the installation, connection and the degree of tightness of the fixed bolt. Tighten it

if necessary.

4) Periodically clean the element of the air cleaner, change it when necessary.

5) The engine is air-cooled, so clean the radiator, wind cover and fan in time in order to make the engine

cool normally.

6) The operator should be familiar with the working principle and structure of the gasoline engine,

knowing how to make an emergent stop and the operation of all controlling parts. Any one without

training is forbidden to operate the engine. Keep periodical maintenance. Solve problems in time. Do

not run the engine in spite of malfunction.

7) Running the engine in a well-ventilated place, keep it at least one meter away from building walls or

other equipments, keep away from inflammables such as gasoline, matches and so on to avoid

possibility of fire.

8) Refuel in a well-ventilated area with the engine stopped, and in places refueling or storing gasoline,

no smoking and any flames or sparks.

9) Refuel the fuel tank not too full so as to avoid fuel

’

s spilling out. If there is spilled fuel around, be sure

to clean it thoroughly before starting.

10) Do not run the engine in airtight or ill-ventilated places.

11) The exhaust muffler is very hot during running the engine even after the engine stops. Never touch it,

or you may get burns. Transport or store the engine with it cooling down entirely.

12) Safe warning label:

Please carefully read warning label before operating. Our company will not assume any responsibility

for person hurt, or equipment damaged caused by disregarding this warning label.

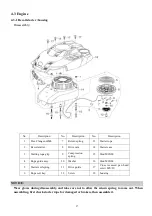

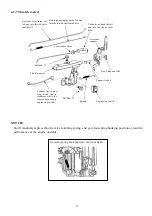

4-2-2 Special tools

Tool name

Application · note

Retainer assembler

Assembler handle

Inner retainer assembler

Diamond lap 45

0

Diamond lap 32

0

Flywheel driver

Bearing extractor

Assembling ball bearing

Installing handle and bearing

Assembling ball bearing and time.

Rectifying valve seat surface.

Rectifying valve seat surface.

Dismounting flywheel

Dismounting flywheel

Summary of Contents for EA190V

Page 1: ...EA190V SERVICE MANUAL...

Page 2: ......

Page 8: ...8 II DIMENSION AND TORQUE 2 1 Engine dimension 2 1 1 Appearance dimension...

Page 9: ...9 2 1 2 Installation hole position 2 1 3 P T O dimension figure Engine Mounting Face...

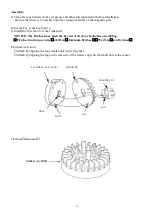

Page 49: ...49 4 4 Electric diagram Engine switch Engine switch Spark plug Ignition coil Black OFF ON...

Page 50: ......

Page 51: ......