41

Tool

:

Valve seat cutter

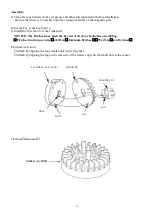

d) Use the 32°-45°cutters to narrow and adjust the valve seat

so that it contacts the middle of the valve face.

・

The 32°cutter removes material from the top edge

(contact too high).

・

The 45°cutter removes material from the bottom edge

(contact too low). Be sure that the width of the finished

valve seat is within specification.

Standard

Service limit

0.8mm

2.0mm

e) Use 45°cutter to remove any possible burrs at the edges of the seat.

f) After resurfacing seat, inspect for even valve seating width.

Apply colorant to the valve tapered face, insert the valve and press

it forcefully several times, be sure the valve does not rotate on the

seat.

The seating surface, as shown by the transferred marking

compound, should have good contact all the way around.

g) Apply the abradant to the valve seat face, suitable for running

in when rotating valve seat with valve seat cutter.

h) After reassembling, check the valve clearance

Cutter holder

IN valve

:

32°

EN valve

:

32°

IN valve

:

45°

EX valve

:

45°

0.8mm

Valve lapping tool

Summary of Contents for EA190V

Page 1: ...EA190V SERVICE MANUAL...

Page 2: ......

Page 8: ...8 II DIMENSION AND TORQUE 2 1 Engine dimension 2 1 1 Appearance dimension...

Page 9: ...9 2 1 2 Installation hole position 2 1 3 P T O dimension figure Engine Mounting Face...

Page 49: ...49 4 4 Electric diagram Engine switch Engine switch Spark plug Ignition coil Black OFF ON...

Page 50: ......

Page 51: ......