18

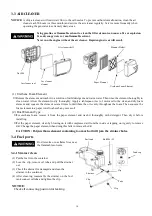

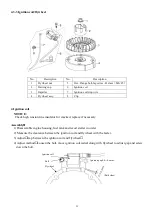

(4) If adjustment is necessary, proceed as follows:

a) Hold valve adjusting bolt with tongs and loosen the valve lock nut

b) Turn valve adjusting bolt to obtain the specified clearance.

c) Fix the valve adjusting bolt with tongs, then fix the valve lock nut with spanner.

d) Recheck valve clearance after tightening the valve lock nut

——

torque value

:

6±2N.m

e) Set the new gasket aligning the projection of the new gaskets with the projection of the cylinder head;

f) Install the cylinder head cover and tighten the four bolts to the specified torque.

bolt torque value

:

8±2N.m

Adjusting bolt

—

screw in: valve clearance becomes smaller

Adjusting bolt

—

screw out: valve clearance becomes bigger

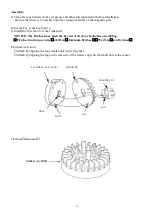

CAUTION:

Clearance too big: Intake and exhaust valve opening delay will shorten the intake and exhaust time, lower

the opening height of the valve and change normal distributing phase to result in power lowering from the

intake lack and exhaust incomplete. Furthermore, also make vale train parts knock increasing and wearing

quick.

Clearance too small: After running, engine parts will be heated to expand and push the valve open,

making the engine closing not tight and result in leaking, power lowering, serious carbon deposit or burn

on the valve surface, even valve

impacting the piston.

Adjusting bolt

Lock nut

Rocker shaft

Rocker

Rocker

Summary of Contents for EA190V

Page 1: ...EA190V SERVICE MANUAL...

Page 2: ......

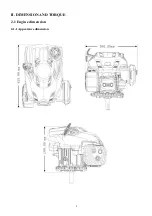

Page 8: ...8 II DIMENSION AND TORQUE 2 1 Engine dimension 2 1 1 Appearance dimension...

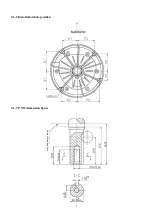

Page 9: ...9 2 1 2 Installation hole position 2 1 3 P T O dimension figure Engine Mounting Face...

Page 49: ...49 4 4 Electric diagram Engine switch Engine switch Spark plug Ignition coil Black OFF ON...

Page 50: ......

Page 51: ......