2

/08.2014/

humidifier

Dampfleistung [kg/h]

Nennleistung [kW]

Nennstrom [A]

Maximalstrom [A]

200 ... 230V / 1N~ / 50 ... 60Hz

2,0

1,5

7,5 ... 6,5

9,4 ... 8,2

4,0

3,0

15,0 ... 13,0

18,8 ... 16,3

200 ... 230V / 3~ / 50 ... 60Hz

4,0

3,0

8,7 ... 7,5

10,8 ... 9,4

8,0

6,0

17,3 ... 15,1

21,7 ... 18,8

10,0

7,5

21,7 ... 18,8

27,1 ... 23,5

380 ... 460V / 3~ / 50 ... 60Hz

4,0

3,0

4,6 ... 3,8

5,7 ... 4,7

8,0

6,0

9,1 ... 7,5

11,4 ... 9,4

15,0

11,25

17,1 ... 14,1

21,4 ... 17,6

EN

Danger that may arise from the unit

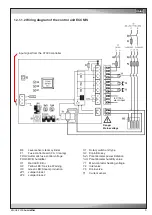

DANGER! Danger of electric hazard!

The steam humidifier OEM2 is operated with mains voltage. One may get in touch with live parts when the unit is

open. Touching live parts may cause severe injury or danger to life.

Prevention

: Before carrying out any work set the steam humidifier OEM2 out of operation as described in chapter

12.1.3.5 (switch off the unit, disconnect it from the mains and stop the water supply) and secure the unit against

inadvertent power-up.

WARNING! Danger of burning!

The steam humidifier OEM2 produces steam. When producing steam, the steam cylinder inside the humidifier gets

very hot (up to 100 °C). If the unit is opened immediately after having produced steam there is danger of burning

when touching the steam cylinder.

Prevention

: Before carrying out any work set the steam humidifier OEM2 out of operation as described in chapter

12.1.3.5, then wait until the steam cylinder has cooled down sufficiently thus preventing danger of burning.

Steam capacity [kg/h]

Nominal power [kW]

Nominal current [A]

Max. current [A]

12.1.1.1 Technical data

Operating conditions

Admissible water pressure

1 ... 10 bar

Water quality

Drinking water with a conductivity of 125 - 1250μS/cm

Admissible water temperature

1 ... 40 °C

Admissible ambient temperature

1 ... 50 °C (control unit 1 ... 40 °C)

Admissible ambient humidity

max. 75% rh, non-condensing

Adm. back pressure at steam connection

- 0,5 kPa ... 1,0 kPa

Type of protection

IP00

Conformity

produced according VDE regulations 0700 and 0700 part 98

Maximum discharge water flow

0,5 l/min (1,2 l/min for the model with 15 kg/h)

Do not treat the water with softeners !

This results in corrosion of the electrodes and in the formation of foam with insufficient filling of

the steam cylinder.

A reverse osmosis plant (ROP) can be used to soften water. The water from the ROP has a low conductivity and

must be mixed with raw water for evaporation.

Summary of Contents for Mini-Space DX CCD131A

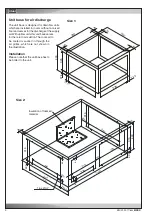

Page 13: ...07 2016 G20 13 EN 5 3 Dimensional drawings Cabinet size 1 Cabinet size 2...

Page 36: ......

Page 58: ...10 01 2017 air_MSDX 150 1000 810 700 160 920 EN Size 2 Filter top with flexible duct...

Page 62: ......

Page 66: ......

Page 70: ......

Page 73: ......