2

/11.2015/

raisedfloor

H

min

— H

max

X

Z

Y

Z (min. 50)

Z (min. 800)

Z

(min. 50)

H

min

—

H

max

[mm]

995 — 1045

895 — 945

795 — 845

695 — 745

595 — 645

495 — 545

355 — 405

270 — 320

EN

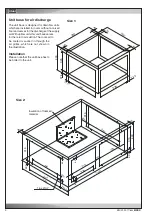

Angle Connection

Butt Joint

Cross Connection

Connecting the bars

(

View from below)

X/Y = Opening in raised floor

Z = Limit of distance

Minimum distances and mounting instructions

Raised floor stand

Recommended concrete

foundations

(no (floor) finish)

Mafund strips

Upper edge of

rough floor

Raised floor support

Raised floor stand

Continuous seal

Raised floor

Raised floor connection

for details, see next page

Hammer head screw M8 x 30

General design of the raised foor stand

Unit width

- Please observe that the floor stand must be decou-

pled from the surrounding floor plates by damping

insertions and that mafund plates are laid under the

floor supports.

- The raised floor cutting (notch) should at least be

15° and must not have any contact to the raised floor

stand, which could result in bone-conduction.

- If the floor stand is placed near a wall, a minimum

distance of 50 mm should be respected. The gap

between wall and floor stand should be closed by tin

stripes.

- The dimensions of the openings in the raised floor

(X and Y) are 10 mm longer than the raised floor

stand. The joint must be closed by customers with a

continuous seal.

- A concrete foundation is recommended in the area

of the raised floor supports.

- The raised floor supports have to be installed on

vibration dampening material (do not screw down the

supports!).

- Prior to installation of the A/C unit, the raised floor must

be installed 7 mm higher than the raised floor plates,

as the mafund plates are compressed by the weight of

the A/C unit.

Summary of Contents for Mini-Space DX CCD131A

Page 13: ...07 2016 G20 13 EN 5 3 Dimensional drawings Cabinet size 1 Cabinet size 2...

Page 36: ......

Page 58: ...10 01 2017 air_MSDX 150 1000 810 700 160 920 EN Size 2 Filter top with flexible duct...

Page 62: ......

Page 66: ......

Page 70: ......

Page 73: ......