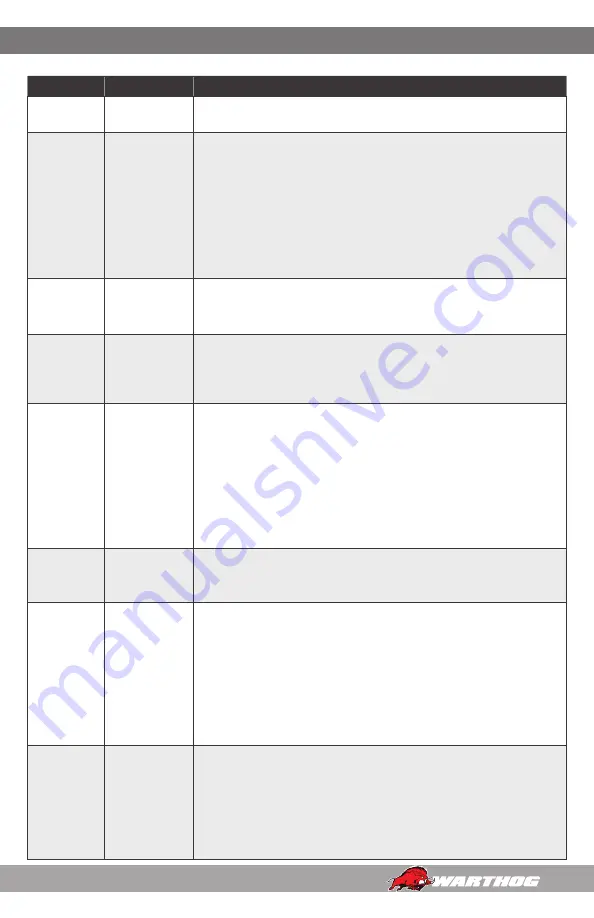

ITEM

FREQUENCY

MAINTENANCE REQUIRED

Nozzle

Weekly

• Rinse the nozzle with clean water to remove debris between the

head, body and shaft.

Inserts

Weekly

• Inspect all inserts for blockages.

• Remove inserts with blockages and clean and dry them thoroughly.

• Use thread sealant and ensure inserts are not cross threaded when

inserting them back into the head.

• Install the inserts back into the exact locations from which they were

removed to ensure the nozzle remains balanced.

• If using the nozzle in recycled water, remove inserts and check for

the following; Erosion or chipping of the orifice, missing or damaged

flow straighteners, and/or visible damage to the insert itself.

Backplates

Weekly

• Inspect the backplate screws.

• If the screws are loose, remove all of them and check screws, body,

and threads are clean and dry.

Fins

Weekly

• Inspect Fins for movement, wear (using wear indicators), and chips

on the ends.

• If the fins are loose, remove all of them and check screws, body, and

threads are clean and dry.

Head

Weekly

• Ensure head is rotating properly; when turned by hand, head should

turn free with slight, smooth resistance.

• If head spins too fast or sounds different than usual, nozzle may be

low on viscous fluid or fluid is contaminated.

• If head feels gritty when turning, flush between head and body.

• If head still feels gritty when turning, rebuild recommended.

• CONTROL CLEAN SWITCHER ONLY- Check the depth of the groove

on the head. If the groove becomes too shallow, it will allow for wear

on the nozzles.

Insert

Orifice

Size

Every 6

months

• Inspect insert orifice size with pin gages.

• Replace inserts as needed to retain most effective jetting capability

and cleaning efficiency during operation.

Body

After one Year

• See “Viscous Fluid Replacement” section of the User Manual.

• Flush viscous fluid with same type (BJ 048-M).

• This procedure is

only

recommended for replacing with the

same

fluid. Not all of the fluid will be replaced during the flushing

procedure, therefore full disassembly and cleaning of the tool is

recommended when changing to a different speed, or viscosity of

fluid.

• Full fluid change is necessary when replacing bearings and shaft

seals.

Nozzle

After two

Years

• Full disassembly, inspection, and overhaul. See complete

Disassembly

and Assembly instructions in the User Manual or Maintenance Video.

(Links provided below.)

• Take care throughout the entire procedure to keep the internals clean

and free from grit, lint, and contamination. Failure to do so could

result in premature failure after service.

WGR SWITCHER ASSEMBLY

WGR MAGNUM AND SWITCHER MAINTENANCE SCHEDULE

25

866-795-1586 • WWW.SEWERNOZZLES.COM