- -

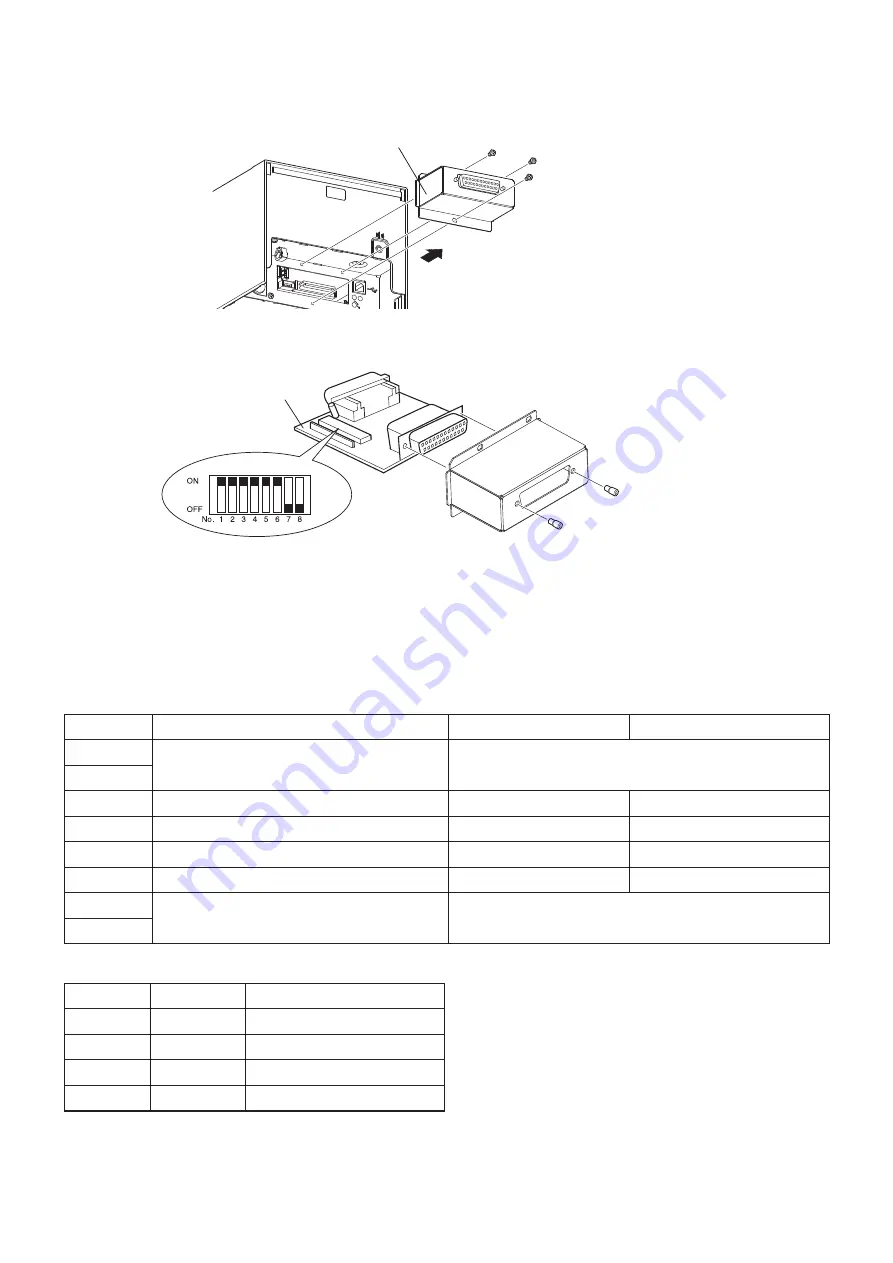

To change DIP-SW 3, which is on the RS-232C interface PCB, follow the instructions given below.

(1) Check that both the printer and the host computer are turned off.

(2) Remove the interface board from the printer.

(3) Remove the interface PCB from the interface board so that you can access DIP-SW 3.

(4) Change the DIP-SW 3 settings.

(5) Attach the RS-232C interface PCB following the procedure for removing it in reverse.

(6) Install the interface board onto the printer.

(7) Turn both the printer and the host computer on.

Note:

The new settings take effect when you turn on the printer.

■

DIP-SW 3

Switch

Function

ON

OFF

-

Baud rate

See the table below.

-

-

Data length

8 bits

7 bits

-

Parity check

Invalid

Valid

-

Parity

Odd

Even

-

Handshaking

DTR

XON/XOFF

3-7

Reserved

Always OFF

-

Baud rate settings

-

-

Baud rate

ON

ON

9600 bps

OFF

ON

4800 bps

ON

OFF

19200 bps

OFF

OFF

38400 bps

By factory default, 3-7 and 3-8 are OFF, and all other settings are ON.

DIP-SW 3

DC

24V

RS-232C interface board

RS-232C interface PCB