- -

5. Consumable Parts and AC Adapter

-

-

Use paper that meets the specifications.

5-1. General Thermal Paper Roll

5-1-1. Paper Roll Specifications

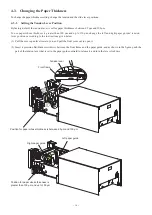

(1) Paper thickness:

65 µm to 150 µm (excluding Mitsubishi HiTec F5041)

(2) Paper width:

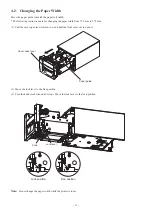

79.5 ± 0.5 mm

57.5 ± 0.5 mm

Note:

Never change the paper width while the printer is in use.

(3) Outer roll diameter: ø83 mm or less

Take up paper roll width: 0

+0.

mm or 58

+0.

mm

(4) Core inner and outer diameters:

65 µm to 75 µm: core inner ø12 ± 1 mm, core outer ø18 ± 1 mm

core inner ø25.4 ± 1 mm, core outer ø32 ± 1 mm

75 µm to 150 µm: core inner ø25.4 ± 1 mm, core outer ø32 ± 1 mm

(5) Printed surface:

Outer edge of roll

* Do not use inner-wrapped paper rolls.

Note 1:

Do not glue or tape the paper roll and shaft core together.

2:

Do not fold the tail end of the paper.

3:

We do not recommend the use of paper that has black marks printed on its near-end-sensor side, because near-end

sensing may fail when the near-end sensor deteriorates.

5-1-2.

Recommended Paper Roll

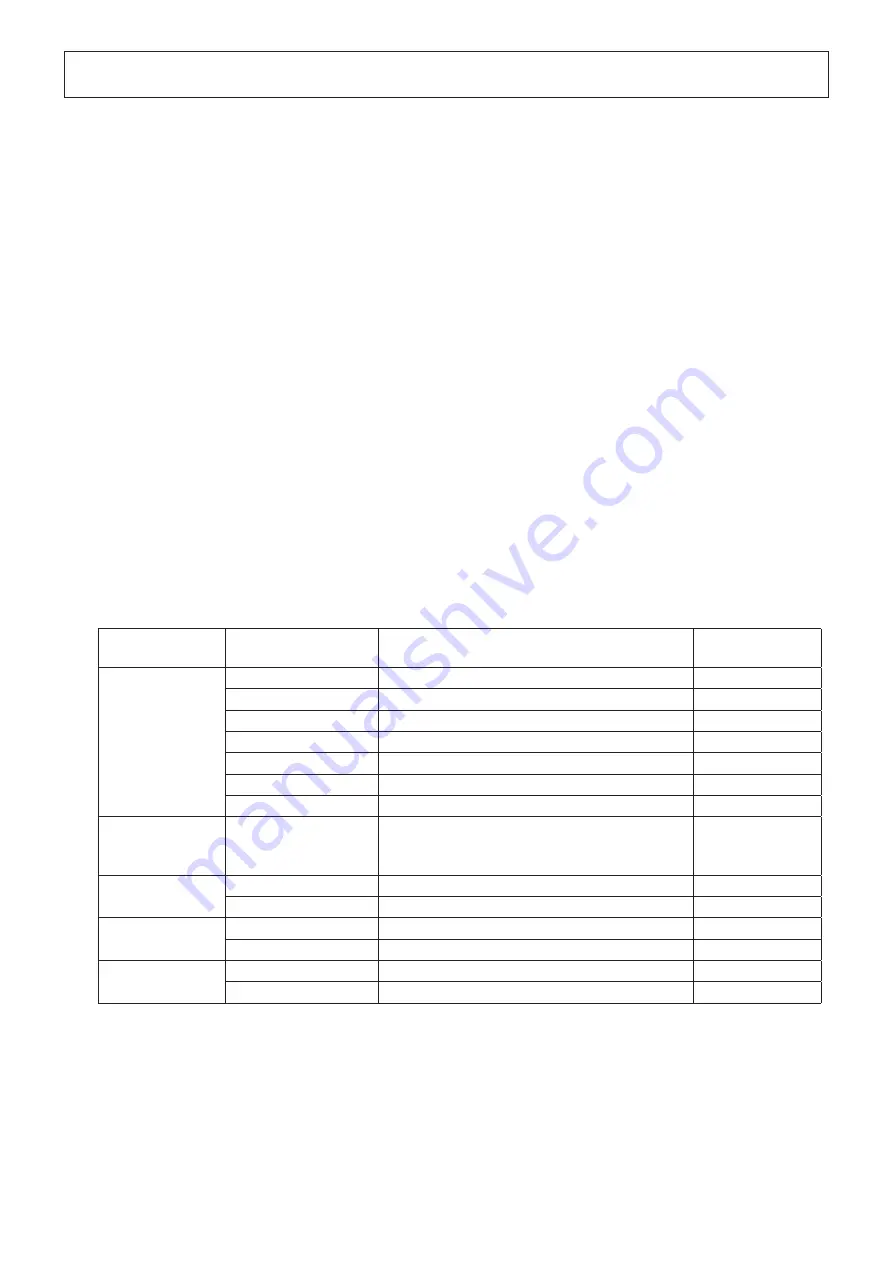

Manufacturer

Product name

Quality characteristics and use

Paper thickness

(µm)

Mitsubishi Paper

Mills Limited

P0AG

normal type paper

HP0A

high image stability paper

HP0AB-

high image stability paper

75

P0AGB

normal type paper, card ticket

0

P0AC-

normal type paper, card ticket

P220AE-1

normal type paper, card ticket

0

PB670

2 color type (red and black)

75

Mitsubishi HiTec

Paper Flensburg

GmbH

F5041

normal type paper

0

Oji Paper Co., Ltd.

PD0R

normal type paper

75

PD0R

high image stability paper

65/75

Nippon Paper

Industries

TF50KS-E2D

normal type paper

TF60KS-E

normal type paper

75

KSP

P-0

normal type paper

P320BB / P320BB

2 color type (red and black, blue and black)

Note 1)

Depending on the type and thickness of the paper, it may be necessary to change the settings for printing dark

-

ness. To change the darkness settings, use the printing darkness settings command <ESC><RS> ‘d’ n. Refer to

the separate programmer’s manual for details.

2)

The print density may vary depending on the type of paper roll, operating environment, and low peak current

mode.

3)

A reader or scanner may not be able to scan a printed bar code or characters depending on the print density.

Make sure that your reader or scanner is able to scan them correctly beforehand.