5.2 Connecting interfaces

Type

Male connector

Female connector

DSL

6

10

Temperature

9

5

Table 1: Male/female connector position

5.2.1

DSL female connector

1

2

3

4

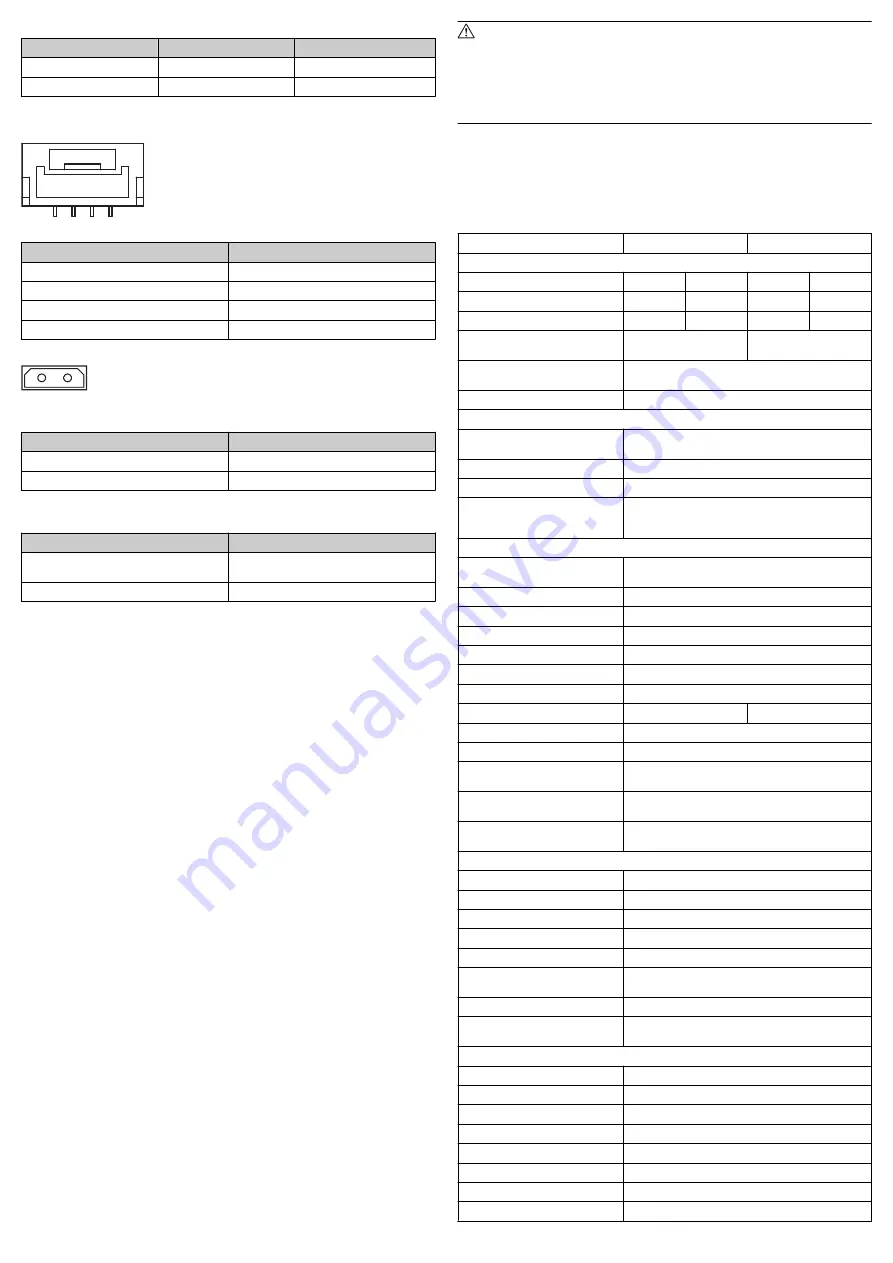

Figure 3: JST BM04B-GHS-GB-TBT (gold-plated) - Device pin assignment

Pin

Signal

1

not assigned (spare)

2

US+ / DSL+

3

GND / DSL-

4

not assigned (spare)

5.2.2

Temperature sensor male connector

2 1

Figure 4: Harwin M80-8820242 - Device pin assignment

Pin

Signal

1

T+

2

T- / GND

5.2.3

Recommended components

Cable connector

Connector

Type

DSL

JST GHR-04V-S (Housing) SSHL-002GA1-

P0.2 (Contact, gold-plated)

Temperature

Harwin M80-xxx-02-XX

Table 2: recommended connector

5.3 Electrical Installation procedure

1.

If necessary, carefully remove the cover (7) from the encoder (12). If neces‐

sary, undo the Torx T08 screw (8) using a screwdriver.

2.

Insert the male connector for the set of DSL stranded wires (6) into the DSL

female connector (10) on the encoder far enough that it clicks into place,

but without mechanical stress.

3.

Optional: Insert the female connector for the temperature sensor (5) into the

temperature sensor male connector (9) without mechanical stress.

4.

Mount the cover (7) and tighten the Torx T08 screw (8). Tightening torque:

0.5 ± 0.05 Nm.

5.

Optional: Attach the shield wire of the set of DSL stranded wires to the

shielding connection (13) using a self-tapping M2.5x5 screw.

5.4 Motor feedback system signals

The motor feedback system has the following signals:

HIPERFACE DSL

®

interface:

•

US+ / DSL+: Supply voltage for the encoder with superimposed positive data

signal. The supply voltage range of the encoder is b7 VDC and

+12 VDC.

•

GND / DSL–: Ground connection of the encoder with superimposed negative

data signal.

•

T+: Sensor signal for passive temperature sensor/temperature resistor.

•

T- / GND: Reference ground for sensor signal of passive temperature sensor/

temperature resistor.

6

Commissioning

To commission the safe motor feedback system, it is assumed that the manufac‐

turer of the connected drive system has complied with the safety requirements for

the drive system design, as described in the “HIPERFACE DSL

®

MASTER” technical

information.

6.1 Checking

During commissioning ensure that an EDS35-2 / EDM35-2 safe motor feedback

system is used and not an EDS35-0 / EDM35-0 standard motor feedback system.

In addition, the POST bit (Power-On-Self-Test) must be set for an EDS35-2 /

EDM35-2 safe motor feedback system after an encoder RESET (hardware or soft‐

ware RESET). The POST bit can be acknowledged after a positive thorough check

(see “HIPERFACE DSL

®

MASTER” technical information).

If the position offset of the motor feedback system is changed using the 101h

(“Set position”) resource or the 108h (“Factory settings”) resource, it is then nec‐

essary to verify that the sensor is providing the required position value.

Further inspection measures are not required during operation.

WARNING

Observe the service life!

The EDS35-2/EDM35-2 safe motor feedback systems have a maximum ser‐

vice life, after which they must always be put out of service. The bearing ser‐

vice life must be taken into account in addition to the mission time. The para‐

meter which is first reached depending on the application determines the

time when the system must be taken out of operation.

The year of manufacture of the motor feedback system is specified on the device

label and/or on the packaging label as a four digit code (yyww). The first two digits

(yy) represent the year (without the century), and the last two digits (ww) repre‐

sent the calendar week of the last manufacturing process.

7

Technical data

Technical specifications

Singleturn

Multiturn

Performance

Resolution per revolution

20 Bit

24 Bit

20 Bit

24 Bit

Position noise (σ)

1

± 3“

± 1“

± 3“

± 1“

System accuracy

2

± 50“

± 25“

± 50“

± 25“

Number of the absolute ascertain‐

able revolutions

1

4,096

Speed when switching on and reset‐

ting the motor feedback system

3

≤ 6,000 min

-1

Available memory area

8,192 bytes

Interface

Code sequence

Increasing on rotation of shaft. Clockwise while looking

towards "A" (see dimensional drawing).

2

HIPERFACE DSL

®

interface signals

4

2-wire H-DSL: Digital, RS485 combined with Power

Initialization time

5

Max. 500 ms

Measurement of external tempera‐

ture resistance

6

Output format: 32 bit value without sign; Output unit:

1 Ω; Measuring range: 0 ... 209,600 Ω Additional recal‐

culation function from PT1000 to KTY84-130

Electrical data

Operating voltage range/supply

voltage

7 V … 12 V

Switch on timing voltage ramp

7

Max. 180 ms

Power consumption

8

Max 1.0 W (Vs = 7 V … 12 V)

Mechanical data

Dimensions

See dimensional drawing

Mass

Max. 100g

Rotor moment of inertia

5 gcm²

Operating speed

Max. 12,000 min

–1

Max. 9,000 min

–1

Max. angular acceleration

250,000 rad/s²

Start-up torque at 20°C

≤ 0.4 Ncm

Permissible shaft movement axial

( dynamic)

± 1 mm

Permissible shaft movement radial

(dynamic

± 0.025 mm

Service life of ball bearings

50,000 h at 6,000 rpm (at defined measuring point of

70 °C)

Ambient conditions

Operating temperature range

9

–40 … +115 °C

Storage temperature range

–40 … +125 °C (without packaging)

Operating altitude

≤ 2,000 m above sea level. (80 kPa)

Relative air humidity/condensation 90 % (condensation impermissible)

Resistance to shocks

1,000 m/s

2

/6 ms (as per EN 60068-2-27:2009)

Resistance to vibrations

500 m/s

2

/10 … 2,000 Hz (as per

EN 60068-2-6:2008)

Protection class

10

IP40 as per IEC 60529:2014

EMC

11

As per EN 61000-6-2:2016, EN 61000-6-4:2006,

IEC 6100-6-7:2014

Safety characteristics

Safety integrity level

12

,

13

SIL2 (IEC 61508:2011), SILCL3 (EN 62061:2010)

Systematic capability

13

SC3 (IEC 61508:2011)

Category

3 (EN ISO 13849-1:2015)

Test rate

24 h

Maximum demand rate

14

216 µs

Performance level

PL d (EN ISO 13849-1:2015)

Safety related resolution

13 bits

Safety related information

Safe Absolute Singleturn Position

8022479 /14FB/2019-06-19/de, en, es, fr, it

EDS35-2.../EDM35-2... | SICK

7