PAGE 52

7.4 ANGLE IRON BRAKE

This brake is designed to form box frames out of angle iron. It has a maximum capacity of 1/4" (6mm).

7.4A ANGLE IRON BRAKE INSTALLATION

SEE FIGURE 24 ON THE FOLLOWING PAGE.

This brake mounts in the punch station and the selector switch must be in the PUNCH position to

operate this tool. The die holder, punch retaining nut and the stripper must be removed to install this

tool. Mount the tool so that it lines up directly under the punch ram and anchor it to the punch bed with

the clamp provided.

7.4B ANGLE IRON BRAKE OPERATION

The down-stroke of the machine must be set, to prevent damage to the tool. Grease the brake guides

every two hours of operation.

ALWAYS REMOVE THIS TOOL WHEN IT IS NOT IN USE!

Summary of Contents for FI-8510-20M

Page 10: ...PAGE 9 FIGURE 1...

Page 12: ...PAGE 11 FIGURE 2...

Page 24: ...PAGE 21 FIGURE 6...

Page 26: ...PAGE 23 FIGURE 7...

Page 38: ...PAGE 35 FIGURE 15...

Page 40: ...PAGE 37 FIGURE 16...

Page 42: ...PAGE 39 FIGURE 17...

Page 48: ...PAGE 45 FIGURE 20...

Page 50: ...PAGE 47 FIGURE 21...

Page 52: ...PAGE 49 FIGURE 22...

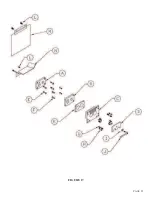

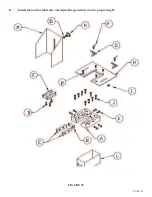

Page 56: ...PAGE 53 FIGURE 24...

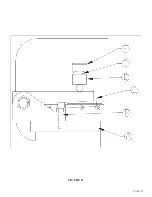

Page 58: ...PAGE 55 FIGURE 25...

Page 62: ...PAGE 59 FIGURE 26...

Page 64: ...PAGE 61 FIGURE 27...

Page 68: ...PAGE 65 FIGURE 29...

Page 74: ...PAGE 71 FIGURE 30...

Page 76: ...PAGE 73 FIGURE 31...

Page 80: ...PAGE 77 FIGURE 33...

Page 82: ...PAGE 79 FIGURE 34...

Page 84: ...PAGE 81 FIGURE 35...

Page 88: ...PAGE 85 FIGURE 37...

Page 90: ...PAGE 87 FIGURE 38...

Page 92: ...PAGE 89 FIGURE 39...

Page 94: ...PAGE 91 FIGURE 40...

Page 96: ...PAGE 93 FIGURE 41...

Page 100: ...PAGE 97 FIGURE 43 SERIAL S 4481 UP...