PAGE 22

5.2 SCHEDULED MAINTENANCE

A program of scheduled maintenance should be set up and documented according to your application

and the frequency you use this machine. The following is a list of some important items that should be

included in a scheduled maintenance program.

Since the FI-8510-20M can be used for a wide variety of applications with many optional tools, every user

must design and implement a scheduled maintenance program that fits their needs.

1.

EVERY 500 HOURS OR SIX MONTHS:

A.

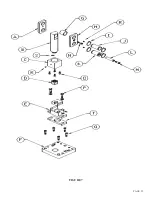

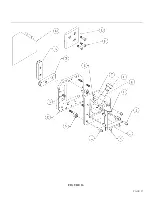

Check the tolerance between the punch ram and the punch ram bushing. For parts identification,

SEE FIGURE 7 ON THE FOLLOWING PAGE.

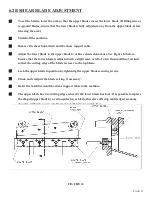

TO CHECK THE CLEARANCE BETWEEN THE RAM AND THE BUSHING:

1.

Install a punch and die following the method outlined IN SECTION 6.1.

2.

Place the run/jog switch in the JOG position. With the punch in the die, jog the machine up and

down several times, watching for any lateral movement of the punch in the die.

3.

If any movement is noted, check the mounting bolts (O) in the punch ram bushing. Make sure

that they are tight. Also, check the bolt (N) through the punch ram straps to make sure that it’s

not so tight that the straps are binding on the arm or the punch ram.

4.

If there is still lateral movement of the punch in the die, remove the punch ram and the bushing

and check the clearance between the two parts.

5.

If the clearance between the two parts is more than five thousandths (.005) of an inch (.12mm),

replace both parts.

B.

Check the condition of all cutting blades on the machine and any optional tools.

C.

Check the condition of the bushings in the drive beam and the upper beam. This can be done

visually by watching the beams for vertical movement while the machine is in operation. The

cylinder shroud on the top of the machine must be removed to view the drive beam. If vertical

movement is noted, block or support the beam with a lifting device and remove the main pin and

check the clearance. If the clearance exceeds twelve thousandths (.012) of an inch (.3mm), replace

the bushing.

2.

EVERY 1,500 HOURS OR 1 YEAR:

A.

Change the hydraulic fluid in the reservoir and replace the filter. For recommended fluids, SEE

SECTION 5.1.

Summary of Contents for FI-8510-20M

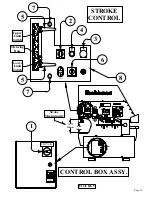

Page 10: ...PAGE 9 FIGURE 1...

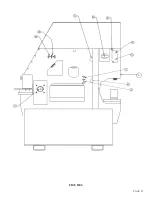

Page 12: ...PAGE 11 FIGURE 2...

Page 24: ...PAGE 21 FIGURE 6...

Page 26: ...PAGE 23 FIGURE 7...

Page 38: ...PAGE 35 FIGURE 15...

Page 40: ...PAGE 37 FIGURE 16...

Page 42: ...PAGE 39 FIGURE 17...

Page 48: ...PAGE 45 FIGURE 20...

Page 50: ...PAGE 47 FIGURE 21...

Page 52: ...PAGE 49 FIGURE 22...

Page 56: ...PAGE 53 FIGURE 24...

Page 58: ...PAGE 55 FIGURE 25...

Page 62: ...PAGE 59 FIGURE 26...

Page 64: ...PAGE 61 FIGURE 27...

Page 68: ...PAGE 65 FIGURE 29...

Page 74: ...PAGE 71 FIGURE 30...

Page 76: ...PAGE 73 FIGURE 31...

Page 80: ...PAGE 77 FIGURE 33...

Page 82: ...PAGE 79 FIGURE 34...

Page 84: ...PAGE 81 FIGURE 35...

Page 88: ...PAGE 85 FIGURE 37...

Page 90: ...PAGE 87 FIGURE 38...

Page 92: ...PAGE 89 FIGURE 39...

Page 94: ...PAGE 91 FIGURE 40...

Page 96: ...PAGE 93 FIGURE 41...

Page 100: ...PAGE 97 FIGURE 43 SERIAL S 4481 UP...