4 Maintenance and servicing

18

SCHMIDT

®

ServoPress 605-660

– V1.1

CAUTION

Contamination of the machine

If the lubrication opening is not covered up again after finishing lubrication,

the functioning of the press can be affected by increasing contamination.

Before starting the press system, insert the cover on top of the

lubrication opening.

Mount the cover of the used grease reservoir.

Mount the inspection cover.

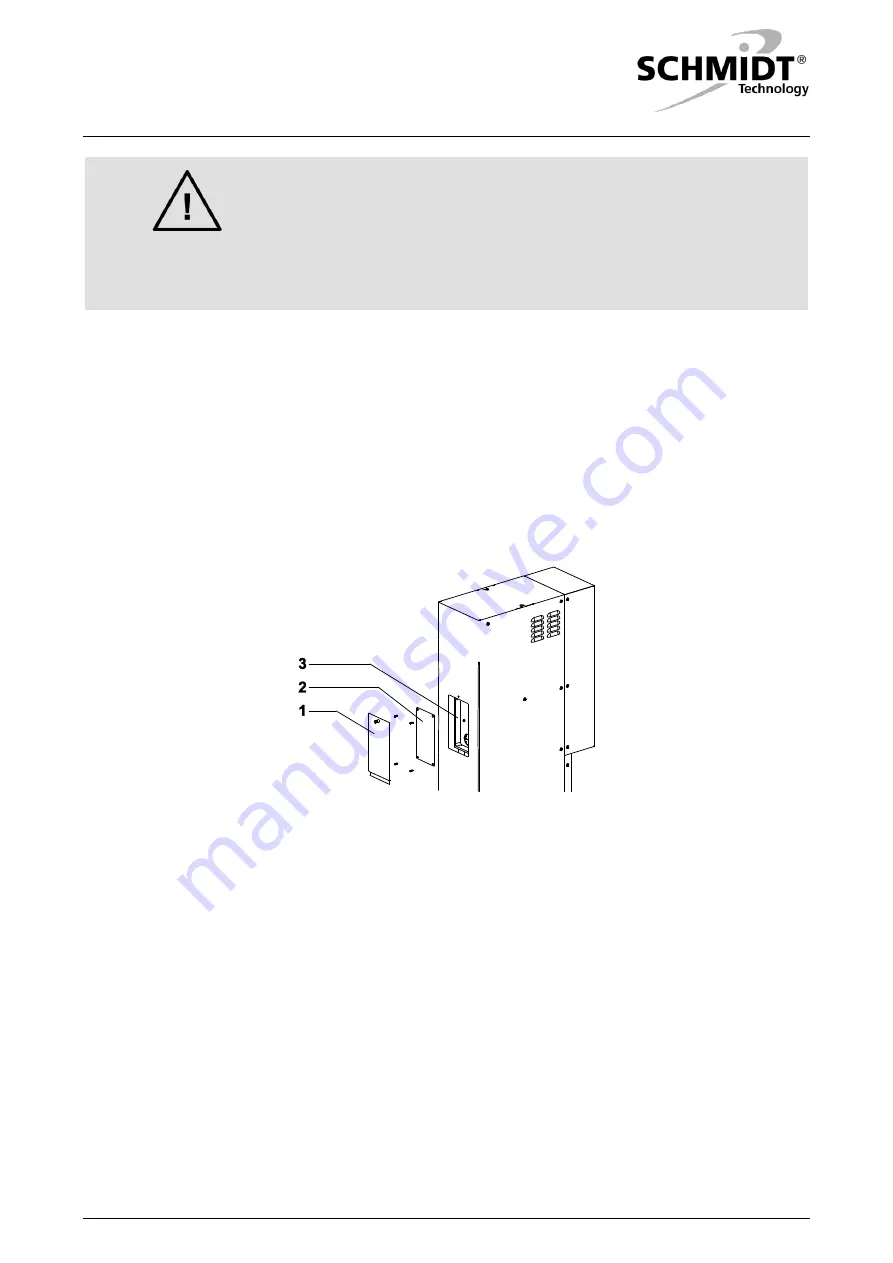

ServoPress 650-660

For the ServoPresses 650-660, the spindle and the spindle bearing is

automatically lubricated via an integrated grease gun.

If the grease cartridge of the grease gun is almost empty, it must be

replaced.

Figure 11: Inspection opening (example)

1

Inspection cover

2

Cover used grease reservoir

3

Used grease reservoir

During each lubrication process, old, used grease is automatically

transported to the used grease reservoir.

Dismount the inspection cover.

Dismount the cover of the used grease reservoir.

Remove the used grease from the reservoir.

Clean the used grease reservoir and the cover of the used grease

reservoir.

Mount the cover of the used grease reservoir.

Mount the inspection cover.

Remove the back cover of the press.

Loosen the grease gun mounting screw.

Cleaning the used

grease reservoir

Replacing the grease

cartridge