3 Assembly and start-up

12

SCHMIDT

®

ServoPress 605-660

– V1.1

You will find ram dimensions, the maximum dimensions and the maximum

weights for the upper tools in chapter "6.1 Technical data".

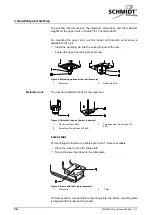

For mounting the upper tool, a centric dowel pin hole with a set screw is

available for fixing it.

Insert the clamping pin into the dowel pin hole of the ram.

Fasten the upper tool using the set screw.

Figure 4: Fastening options at the ram (example)

1

Set screw

2

Dowel pin hole

The ram has a distortion lock for the upper tool.

Figure 5: Distortion lock on the ram (example)

1

Slot (ServoPress 605)

2

Dowel hole (ServoPress 616-660)

3

Threaded hole (ServoPress 616-

660)

Lower tool

For mounting the lower tool, a table bore and a T-slot are available.

Place the lower tool on the table plate.

Screw the lower tool down to the table plate.

Figure 6: Frame with table plate (example)

1

Table bore

2

T-Slot

For frames with a screwed fixture mounting plate, the fixture mounting plate

is aligned with the ram but not pinned.

Distortion lock