2 ServoPress

SCHMIDT

®

ServoPress 605-660

– V1.1

7

2 ServoPress

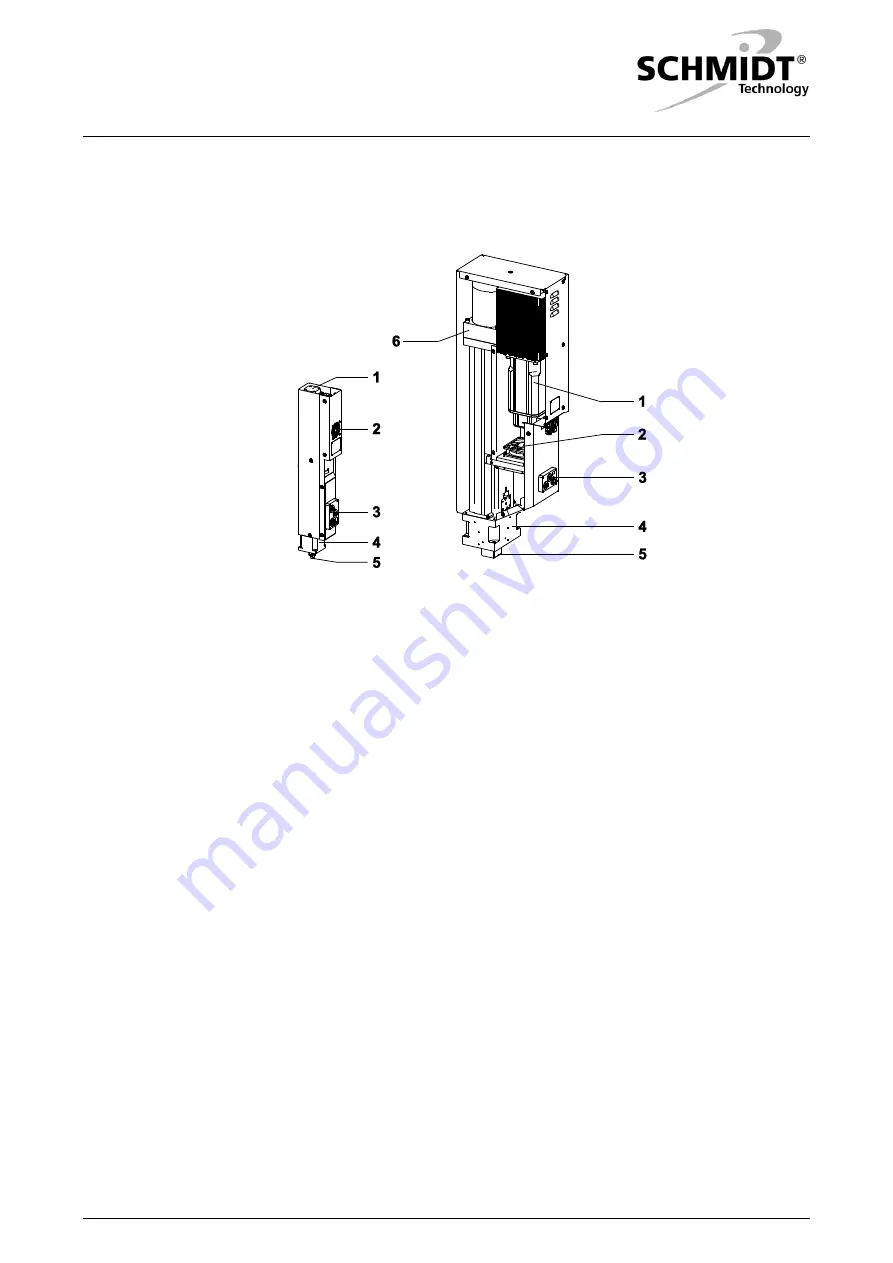

2.1 Structure

Figure 1: Structure (example)

1

Servo motor

2

Fan

3

Process data acquisition

4

Flange

5

Ram

6

Belt drive

2.2 Function

When using the ServoPress, the force of the servo motor is transmitted to

the ram via a backlash-free spindle drive.

The presses 605-617 are equipped with a ball screw. The presses 620-660

with a planetary roller screw.

The motor is controlled by the servo converter according to the parameters

(position, force and speed) defined in the control. Thus the ram travels along

the defined operating profile.

The servo converter and the power supply unit are located in a switch

cabinet.

The integrated brake is used as device for retention of ram in home position

and prevents the lowering of the ram in currentless condition.

In case of an overload, the ServoPresses 616-660 have a mechanical clutch

that separates the motor from the drive.

The maintenance-free, temperature-controlled fan built into the ServoPress

ensures highly reliable operation.

The "stroke" measurement is carried out via an absolute position measuring

system directly on the ram. The "force" signal is detected via an integrated

force sensor.

These signals are processed and evaluated in process data acquisition. The

results are then transmitted to the connected control unit.

Force/stroke-

monitoring