4 Maintenance and servicing

SCHMIDT

®

ServoPress 605-660

– V1.1

15

4 Maintenance and servicing

CAUTION

Safety instructions

The press must only be serviced by a skilled person.

Any work on the electrical equipment of the press must be carried out

only by trained electricians or by specially instructed persons under the

control and supervision of a trained electrician and in accordance with

the applicable electrical engineering rules and regulations.

All spare parts must comply with the technical requirements specified

by SCHMIDT Technology. This is always guaranteed in the case of

original spare parts.

Unless expressly described otherwise, do not start with the maintenance and

servicing work until

the press has been disconnected from the power/voltage supply,

the press system has been switched off and secured against being

switched on again,

the dangerous movements have come to a standstill,

unauthorized, inadvertent or unexpected starting of dangerous

movements as a result of stored energy is prevented.

Interval

Activity

Every week

(every 50 operating hours)

see chapter "4.1 Cleaning the press and the ram"

Every year

(every 3,000 operating hours)

see chapter "4.2 Adjusting the force measurement"

Automatically

(suggested by the control)

see chapter "4.3 Lubricating the spindle"

Automatically

(suggested by the control)

see chapter "4.4 Filling the grease reservoir"

Further information about the necessary activities you get in the individual

chapters.

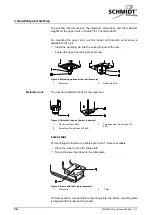

4.1 Cleaning the press and the ram

CAUTION

In any case do not use any solvent based cleaners.

Clean the press with a lightly oiled cloth.

Move the ram to the BDC position.

Maintenance intervals

Press

Ram