4 Maintenance and servicing

SCHMIDT

®

ServoPress 605-660

– V1.1

17

the used grease reservoir

the lubrication nipples (ServoPress 605-620)

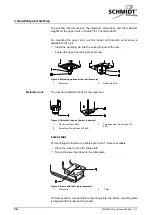

Figure 10: Inspection opening (example)

1

Inspection cover

2

Cover used grease reservoir

3

Used grease reservoir

4

Lubrication nipples

During each lubrication process, old, used grease is automatically

transported to the used grease reservoir.

Dismount the inspection cover.

Dismount the cover of the used grease reservoir.

Remove the used grease from the reservoir.

Clean the used grease reservoir and the cover of the used grease

reservoir.

The grease reservoir must be filled with a grease gun.

Remove the cover of the lubrication opening (only ServoPress 620).

Use a grease gun to press in grease at the lubrication nipple.

Insert the cover in the lubrication opening (only ServoPress 620).

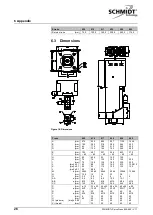

Press type

Amount of

grease

required

Grease

Material no.

605

28 cm

3

KLÜBERPLEX BEM 34-131N

554906 (grease

cartridge)*

616

44 cm

3

KLÜBERPLEX BEM 34-131N

554906 (grease

cartridge)*

617

64 cm

3

KLÜBERPLEX BEM 34-131N

554906 (grease

cartridge)*

620

69 cm

3

KLÜBERPLEX BEM 34-131N

554906 (grease

cartridge)*

* A maintenance set (material no. 564524), which includes a grease gun, a grease cartridge and

a hose, is optionally available.

Cleaning the used

grease reservoir

Filling the grease

reservoir