4 Maintenance and servicing

16

SCHMIDT

®

ServoPress 605-660

– V1.1

Clean the ram with a lightly oiled cloth.

Clean the scale on the ram with a soft, lint-free cloth wetted with

isopropyl alcohol.

4.2 Adjusting the force measurement

Since the force-measuring system is usually used for measuring

characteristic quantities relevant to quality, it should be calibrated and, if

necessary, adjusted at reasonable intervals established by the owner. EN

ISO 9001 (Quality management systems - Requirements) makes a

calibration of the system mandatory at regular intervals.

Calibration is also offered as a service by the SCHMIDT Customer Service.

4.3 Lubricating the spindle

The lubrication of the spindle is stroke-dependent. Depending on the

configured operating profile, the point in time for the next lubrication is

calculated. When the given time has come, the control will request you to

lubricate.

For further information, refer to the "Instructions for Use - SCHMIDT Manual

workstation"

respectively

the

"Assembly

Instructions

-

SCHMIDT

Components for automation".

4.4 Filling the grease reservoir

WARNING

Shearing of finger(s)

The upward or downward movement of the used grease depot or spindle

nut creates a danger zone during operation of the press. Fingers can be

sheared off when reaching into this danger zone.

Mount the inspection cover on the inspection opening before switching

on the press system.

NEVER

operate the press without the inspection cover installed.

If the grease reservoir is almost empty, a message to refill the grease

reservoir is displayed.

To fill the grease reservoir, the ram of the press moves to a special position.

This happens automatically after answering the message.

If you are prompted ...

Switch off the press system with the main switch on the switch cabinet.

ServoPress 605-620

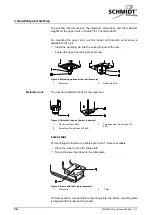

For the ServoPresses 605-620, the grease reservoir must be filled manually

using the lubrication nipple.

There is an inspection opening at the front of each press. Underneath is

Switching off the press

system