EB 8048-2/-3 EN

37

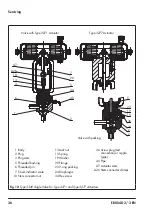

Servicing

10. Place the flange (20) together with the

plug stem (3), plug (2), and diaphragm

(24) onto the body (1).

11. Apply a suitable lubricant to the hex

screws (34).

12. Tighten the hex screws (34) on the flange

(20) gradually in a crisscross pattern.

Observe tightening torques.

13. Mount actuator. See associated actuator

documentation.

14. Adjust lower or upper signal bench

range. See associated actuator docu-

mentation.

7.1.2

Replacing the dia

-

phragm and plug

1. Remove the actuator from the valve. See

associated actuator documentation.

2. Undo the hex screws (34).

3. Lift the flange (20) together with the plug

stem (3), plug (2), and diaphragm (24)

off the body (1).

4. Pull the plug (2) together with plug stem

(3) and diaphragm (24) out of the flange

(20).

For version with packing:

replace the

packing (see section 7.1.1).

5. Unscrew the threaded pin (6).

6. Unscrew the plug stem (3) from the plug

(2).

7. Remove diaphragm (24).

8. Apply a suitable lubricant to the thread

of the plug stem (3).

9. Screw a new plug (2) onto the plug stem

(3) using a suitable tool. Observe tight-

ening torques.

10. Mark the side mounting position.

11. Unscrew the plug stem (3) from the plug

(2).

12. Insert a new diaphragm (24) into the

new plug.

13. Screw the new plug (2) back onto the

plug stem (3) again using a suitable tool.

Align the plug stem with the mounted po-

sition mark made earlier. To do this,

clamp the plug into a suitable clamping

fixture and pull it with a suitable tool.

14. Remove the mounting position mark.

15. Secure the plug (2) with threaded pin

(6).

16. Check the concentricity of the plug (see

section 7.3).

17. Push the plug (2) together with plug stem

(3) and diaphragm (24) into the flange

(20).

18. Place the flange (20) together with the

plug stem (3), plug (2), and diaphragm

(24) onto the body (1).

19. Apply a suitable lubricant to the hex

screws (34).

20. Tighten the hex screws (34) on the flange

(20) gradually in a crisscross pattern un-

til the valve bonnet touches the body

flange.

Greater deformation forces are required for

new diaphragms (in comparison to already

Note