EB 8048-2/-3 EN

35

Servicing

Risk of contamination of the process medium

through the use of unsuitable lubricant and/

or contaminated tools and components.

−

Keep the valve and the tools used free from

solvents and grease.

−

Make sure that only suitable lubricants are

used (

u

The control valve was checked by SAMSON

before it left the factory.

−

Certain test results (seat leakage and leak

test) certified by SAMSON lose their validi

-

ty when the valve body or actuator hous

-

ing is opened.

−

The product warranty becomes void if

service or repair work not described in

these instructions is performed without

prior agreement by SAMSON's After‑sales

Service department.

−

Only use original spare parts by

SAMSON, which comply with the original

specifications.

Checking the extent of servicing

Î

Check wear at seat and plug. Replace

the damaged plug (see section 7.1.2 or

7.2.2).

Î

Check the diaphragm for damage (e.g.

cracks, milky coloring at the bends). Re-

place the damaged diaphragm (see sec-

tion 7.1.2 or 7.2.2).

Î

If the valve leaks even if the diaphragm

is intact, check the tightening torque of

the joint between plug and plug stem as

well as body and bonnet/flange.

Preparing the valve for servicing

1. Put the control valve out of operation (see

section 9.1).

2. Remove the valve from the pipeline (see

section 9.2).

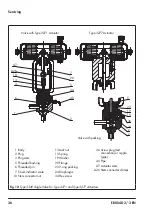

7.1

Version with Type 3271 or

Type 3277 Actuator

7.1.1

Replacing the packing

1. Remove the actuator from the valve. See

associated actuator documentation.

2. Undo the hex screws (34).

3. Lift the flange (20) together with the plug

stem (3), plug (2), and diaphragm (24)

off the body (1).

4. Unscrew the threaded bushing (5).

5. Pull the plug (2) together with plug stem

(3) and diaphragm (24) out of the flange

(20).

6. Pull all the packing parts out of the pack-

ing chamber using a suitable tool. Renew

the damaged parts and carefully clean

the packing chamber.

7. Push the plug (2) together with plug stem

(3) and diaphragm (24) into the flange

(20).

8. Carefully slide the packing parts over the

plug stem into the packing chamber us-

ing a suitable tool.

9. Tighten the threaded bushing (5).

NOTICE

!

Note