EB 8048-2/-3 EN

31

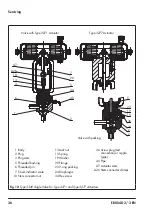

Mounting and start-up

5.4

Quick check

SAMSON valves are delivered ready for

use. To test the valve's ability to function, the

following quick checks can be performed:

Tight shut-off

1. Close the valve.

2. Slowly open the shut-off valve in the

pipeline.

Risk of valve damage due to a sudden pres

-

sure increase and resulting high flow veloci

-

ties.

Slowly open the shut‑off valve in the pipeline

during start‑up.

3. Check the valve for leakage (visual in-

spection).

Travel motion

The movement of the actuator stem must be

linear and smooth.

Î

Open and close the valve, observing the

movement of the actuator stem.

Î

Apply the maximum and minimum con-

trol signals to check the end positions of

the valve.

Î

Type 3349-1 and Type 3349-7:

check

the travel reading at the travel indicator

scale.

Fail-safe position

Î

Shut off the signal pressure line.

Î

Check whether the valve moves to the

fail-safe position.

Pressure test

During the pressure test, make sure the fol-

lowing conditions are met:

−

Retract the plug stem to open the valve.

−

Observe the maximum permissible pres-

sure for valve and plant.

The plant operator is responsible for per-

forming the pressure test. SAMSON's Af

-

ter‑sales Service department can support you

to plan and perform a pressure test for your

plant.

NOTICE

!

Note