34

EB 8048-2/-3 EN

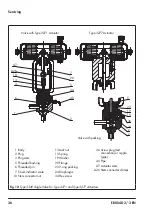

Servicing

7

Servicing

The control valve is subject to normal wear,

especially at the diaphragm, seat, plug, and

packing. Depending on the operating condi-

tions, check the valve at regular intervals to

prevent possible failure before it can occur.

SAMSON's After‑sales Service department

can support you to draw up an inspection

plan for your plant.

Risk of bursting in pressure equipment.

Control valves and pipelines are pressure

equipment. Improper opening can lead to

valve components bursting.

−

Before starting any work on the control

valve, depressurize all plant sections con

-

cerned as well as the valve.

−

Drain the process medium from all the

plant sections concerned as well as the

valve.

−

Wear personal protective equipment.

Risk of personal injury due to residual pro

-

cess medium in the valve.

While working on the valve, residual process

medium can escape and, depending on its

properties, may lead to personal injury, e.g.

(chemical) burns.

Wear protective clothing, safety gloves, and

eyewear.

Risk of burn injuries due to hot or cold com

-

ponents and pipeline.

Valve components and the pipeline may be

-

come very hot or cold. Risk of burn injuries.

−

Allow components and pipelines to cool

down or heat up.

−

Wear protective clothing and safety gloves.

Risk of valve damage due to incorrect

servicing or repair.

Service and repair work must only be

performed by trained staff.

Risk of valve damage due to excessively high

or low tightening torques.

Observe the specified torques on tightening

control valve components. Excessively tight

-

ened torques lead to parts wearing out

quicker. Parts that are too loose may cause

leakage.

Observe the specified tightening torques

(

u

Risk of valve damage due to the use of un

-

suitable tools.

Only use tools approved by SAMSON

(

u

Tip

DANGER

!

WARNING

!

WARNING

!

NOTICE

!

NOTICE

!

NOTICE

!