40

EB 8048-2/-3 EN

Servicing

3.

"Actuator stem extends" fail-safe ac

-

tion:

guide the locking pin (Ø 3.5 mm)

through the hole located in the bottom

actuator section and the actuator stem.

"Actuator stem retracts" fail-safe action:

apply 6 bar signal pressure to the actua-

tor. Guide the locking pin (Ø 3.5 mm)

through the hole located in the bottom

actuator section and the actuator stem.

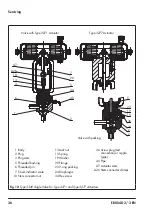

4. Unscrew the plug stem (3) together with

plug (2) and diaphragm (24) from the

actuator stem and pull it out of the valve

bonnet (20).

5. Unscrew the actuator (A) from the valve

bonnet (20).

6. Remove locking pin.

7. Compress the packing using a suitable

tool and remove the snap ring (42).

8. Pull all the packing parts out of the pack-

ing chamber using a suitable tool. Renew

the damaged parts and carefully clean

the packing chamber.

9. Check the plug and diaphragm for dam-

age. Replace them, if necessary (see sec-

tion 7.2.2).

10. Push the plug (2) together with plug stem

(3) and diaphragm (24) into the valve

bonnet (20).

11. Carefully slide the packing parts over the

plug stem into the packing chamber us-

ing a suitable tool.

12. Compress the packing using a suitable

tool and insert the snap ring (42).

13. Screw the actuator (A) onto the valve

bonnet (20).

14.

"Actuator stem extends" fail-safe ac

-

tion:

guide the locking pin (Ø 3.5 mm)

through the hole located in the bottom

actuator section and the actuator stem.

"Actuator stem retracts" fail-safe action:

apply 6 bar signal pressure to the actua-

tor. Guide the locking pin (Ø 3.5 mm)

through the hole located in the bottom

actuator section and the actuator stem.

15. Apply a suitable lubricant to the actuator

stem.

16. Screw the plug stem (3) together with

plug (2) and diaphragm (24) onto the

actuator stem. Observe tightening

torques.

17. Remove locking pin.

18. Place the actuator and valve bonnet (20)

together with the plug stem (3), plug (2),

and diaphragm (24) onto the body (1).

19. Apply a suitable lubricant to the hex

screws (34).

20. Tighten the hex screws (34) on the valve

bonnet (20) gradually in a crisscross pat-

tern. Observe tightening torques.

21. For version with Type 3724 Positioner:

initialize the positioner (

u

7.2.2

Replacing the dia

-

phragm and plug

Before replacing the diaphragm and plug,

remove the valve from the plant.

Note