Automatic Backflush Filter F450

State:

05.02.2016

– 1.3

Georg Schünemann GmbH, Bremen

6-1

6

Maintenance

In this chapter all necessary maintenance of the automatic backflush filter F450 is

described in detail.

It is absolutely necessary to ensure that the filter is not under pressure before

starting maintenance, because the automatic backflush F450 is a pressure ves-

sel and that it is drained, if the filter shall be opened.

The automatic backflush filter F450 is extensively maintenance free.

It is recommended to clean the strainer insert thoroughly depending upon oper-

ation conditions - however at least once in a year - to control and if necessary

replace the wearing parts.

If you order spare and wear parts in the course of maintenance work, please

always give the order number of the filter (the serial-no. on the name plate).

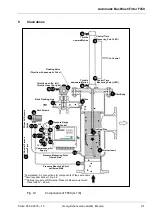

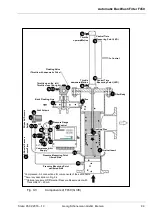

The individual components described in the following are also illustrated in chap-

ter 9

6.1

Cleaning of strainer insert

Close the throttle at LS1 (see Fig. 9-1 resp. Fig. 9-3/ 3a) and note the num-

ber of turns. Later at recommissioning the throttle has to be opened up to

their primary adjustment.

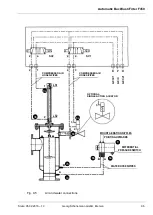

Remove the compressed air connections and resp. disconnect the piping at

the therefore intended fittings and remove the proximity switches (LS1 and

LS2) from the pneumatic cylinder.

Loosen the cover screws and carefully raise the cover including the pneu-

matic cylinder and flushing disc (cover assembly) with a suitable and tech-

nical proper lifting device with sufficient load capacity. Take enough safety

clearance to the perched parts.

Place the unit carefully on the ground.

After removing the sieve nuts and washers the filter insert can be taken out,

cleaned and inspected. In case of damages it has to be replaced.

6.2

Flushing disc

After removing the cover assembly the flushing disc, mounted at the lower

end of the piston rod of the pneumatic cylinder, may be inspected. In case of

damages it has to be replaced.