Automatic Backflush Filter F450

State:

05.02.2016

– 1.3

Georg Schünemann GmbH, Bremen

4-5

4.4

Steps for setting into operation

The following procedures have to be done before setting into operation:

1.

Before setting into operation check the proper condition of the electric ca-

bles and connections of the control (Check the cable connections for fixed

fit).

2.

Check the compressed air adapters. The distribution of compressed air

must be supplied with 94 psi (6.5 kg/cm

2

) / Special 50.7

– 116 psi (3.5 – 8

kg/cm

2

), check with pressure gauge. Check before setting into operation

whether the distribution of compressed air, the solenoid valve and the

pneumatic cylinder (drive of the flushing disc) are properly supplied with

compressed air.

3.

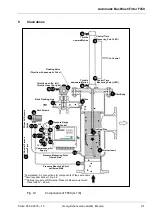

Check the differential pressure connection (DDS/DDT). The differential

pressure hoses/pipes (Fig. 9-1 resp. Fig. 9-3 / 9) must be attached to the

intended pressure measuring points (Fig. 9-1 resp. Fig. 9-3 / 7a, 7b) in the

lower region of the filter (inlet), as well as to the appertained differential

pressure switch (Fig. 9-1 resp. Fig. 9-3 / 8a, 8b). The differential pressure

switch must be duly aired out by means of the vent screws (Fig. 9-1 resp.

Fig. 9-3 / 8c). The same applies at a special design with a differential pres-

sure transmitter for a differential pressure registration.

In case of ATEX-specification the deaeration of the measurement pipes

takes place by two separate valves, connected upstream of the differential

pressure switch.

No operation without control

In order to avoid damage to the filter, the strainer insert and the plant, never op-

erate the filter without the control!

The operation without liquid is not damaging the filter. At emptying from pipes

therefore it is not necessary to set the filter out of operation for its own protec-

tion.