15

on and at the same time the output current will be cut off. It can self-protect, prolong the usefull

life, greatly improved the reliability and practicality of the welding machine.

ARC series of welding machines can also realize TIG operation. While MMA operation, if

the electrode touches workpiece over two seconds, the welding current will drop to the minimum

current automatically to protect the electrode. While TIG operation, the minimum current will be

outputted firstly until the arc is ignited by lifting method, the output current will rise to the pre-set

value, which can protect the electrode.

ARC series of welding machines is widely used in Petroleum, chemical, mechanical,

shipbuilding, architecture, boiler, pressure container, military industry and Maintenance work, etc.

This machine has high duty cycle even in the 40

℃

, which can keep the continuous operation. The

frame is Stability of the machine, which can keep working under high temperature and corrosion

environment.

MMA — Manual Metal Arc welding;

PWM — Pulse-Width Modulation;

IGBT — Insulation Gate Bipolar Transistor;

TIG — Tungsten Inert Gas welding.

•

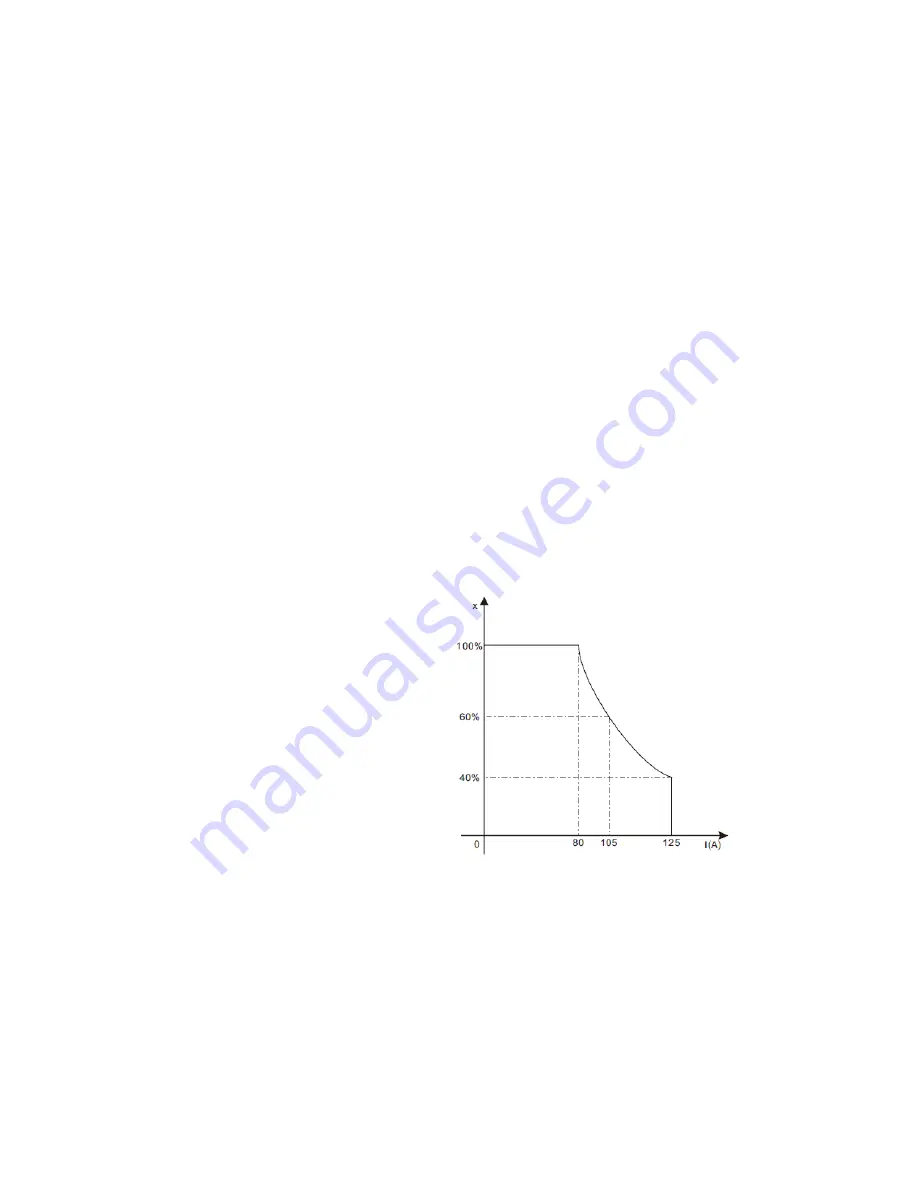

2.4. Duty cycle and Over-heat

The letter “X” stands for Duty Cycle,

which is defined as the portion of the time a

welding machine can weld continuously with

it’s rated output current within a certain

time cycle (10 minutes).

The relation between the duty cycle

“X” and the output welding current “I” is

shown as the right figure.

If the welding machine is

overheating, the IGBT over-heat protection

sensing will send a signal to the welding

machine control unit to cut the output

welding current OFF and light the over-heat pilot lamp on the front panel. In that case, the

machine should not be welding for 10-15 minutes to cool down with the fanrunning. When

operating the machine again, the welding output current or the duty cycle should be reduced.

Relation of welding current

and duty cycle for

ARC 125 LT DV