20

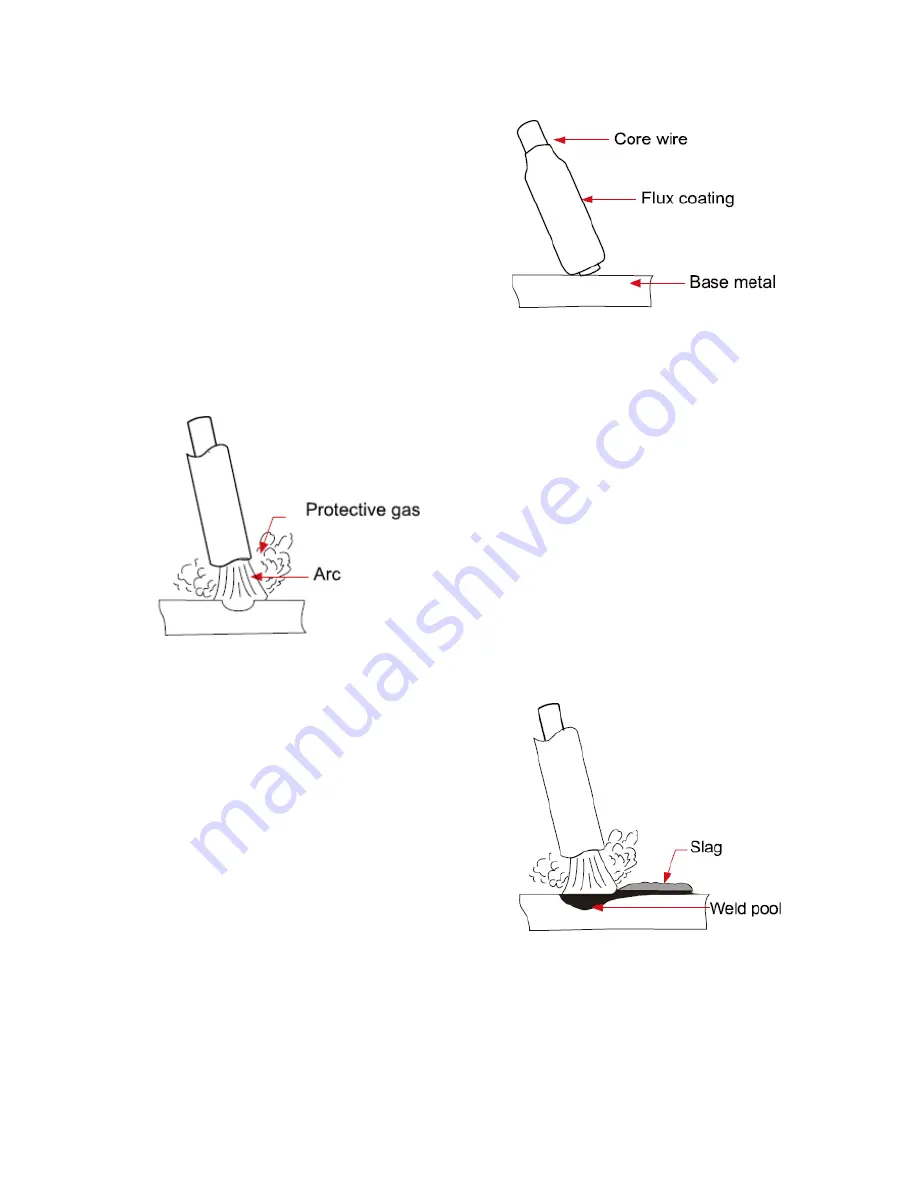

The arc is initiated by momentarily

touching the electrode to the base

metal.

The heat of the arc melts the surface of

the base metal to form a molten pool at

the end of the electrode.

The melted electrode metal is

transferred across the arc into the

molten pool and becomes the deposited

weld metal.

The deposit is covered and protected by

a slag which comes from the electrode

coating.

The arc and the immediate area are enveloped by an atmosphere of protective gas.

Manual metal arc (stick) electrodes have a solid

metal wire core and a flux coating. These electrodes

are identified by the wire diameter and by a series

of letters and numbers. The letters and numbers

identify the metal alloy and the intended use of the

electrode.

The

Metal Wire Core

works as conductor of the

current that maintains the arc. The core wire melts

and is deposited into the welding pool.

The covering on a shielded metal arc

welding electrode is called

Flux

.

The flux on the electrode performs many diferent

functions.

These include:

producing a protective gas around the

weld area

providing fluxing elements and deoxidizer

creating a protective slag coating over the

weld as it cools

establishing arc characteristics

adding alloying elements.

Covered electrodes serve many purposes in addition to filler metal tothe molten pool. These

additional functions are provided mainly by the covering on the electrode.