17

3. Installation & Operation

•

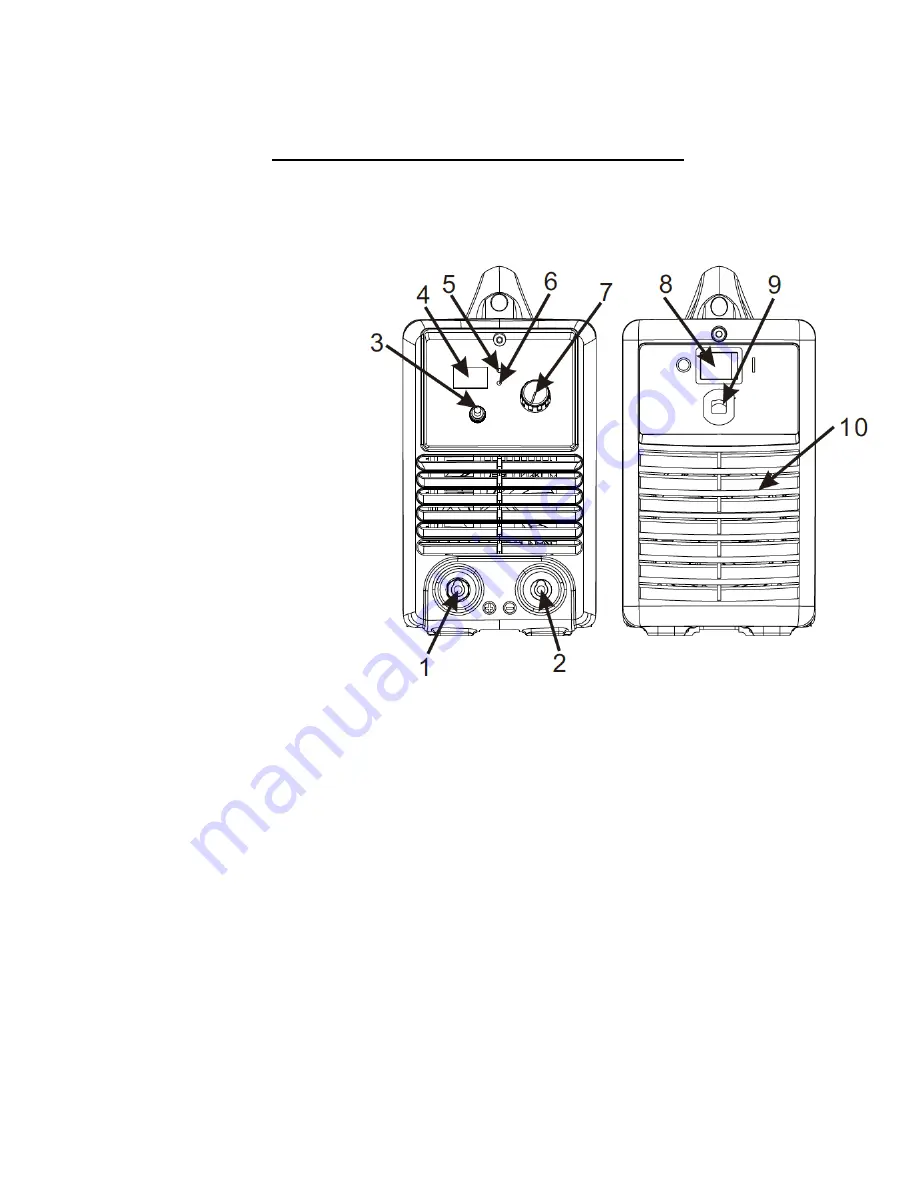

3.1. Layout for the front and rear panel

(1)

“+” Output terminal.

(2)

“-” Output terminal.

(3)

Conversion switch:

Choose (left) LIFT TIG;

choose (right) MMA.

(4)

Current digital display.

(5)

Power light: Power

indicator, power on

light on.

(6)

Alarm light: Alarm

indicator, lights that

occurred over voltage,

over current, or

overheating inside the

machine, is protected.

(7)

Welding current

adjustment knob: Turn

this knob to adjust the

output current size.

(8)

Power switch: control

power through and

break.

(9)

Power Access client: access to cable.

(10)

Fan: Help plant cooling.

•

3.2. Installation for MMA Welding

•

3.2.1. Set up installation for MMA Welding

Connection of Output Cables

Two sockets are available on this welding machine. For MMA welding the electrode holder is

shown be connected to the positive socket, while the earth lead (work piece) is connected to the

negative socket, this is known as DCEP. However various electrodes require a different polarity for

optimum results and careful attention should be paid to the polarity, refer to the electrode

manufacturers information for the correct polarity.

DCEP: Electrode connected to “+” output socket.

DCEN: Electrode connected to “-“ output socket.