17

5 Installing the Software

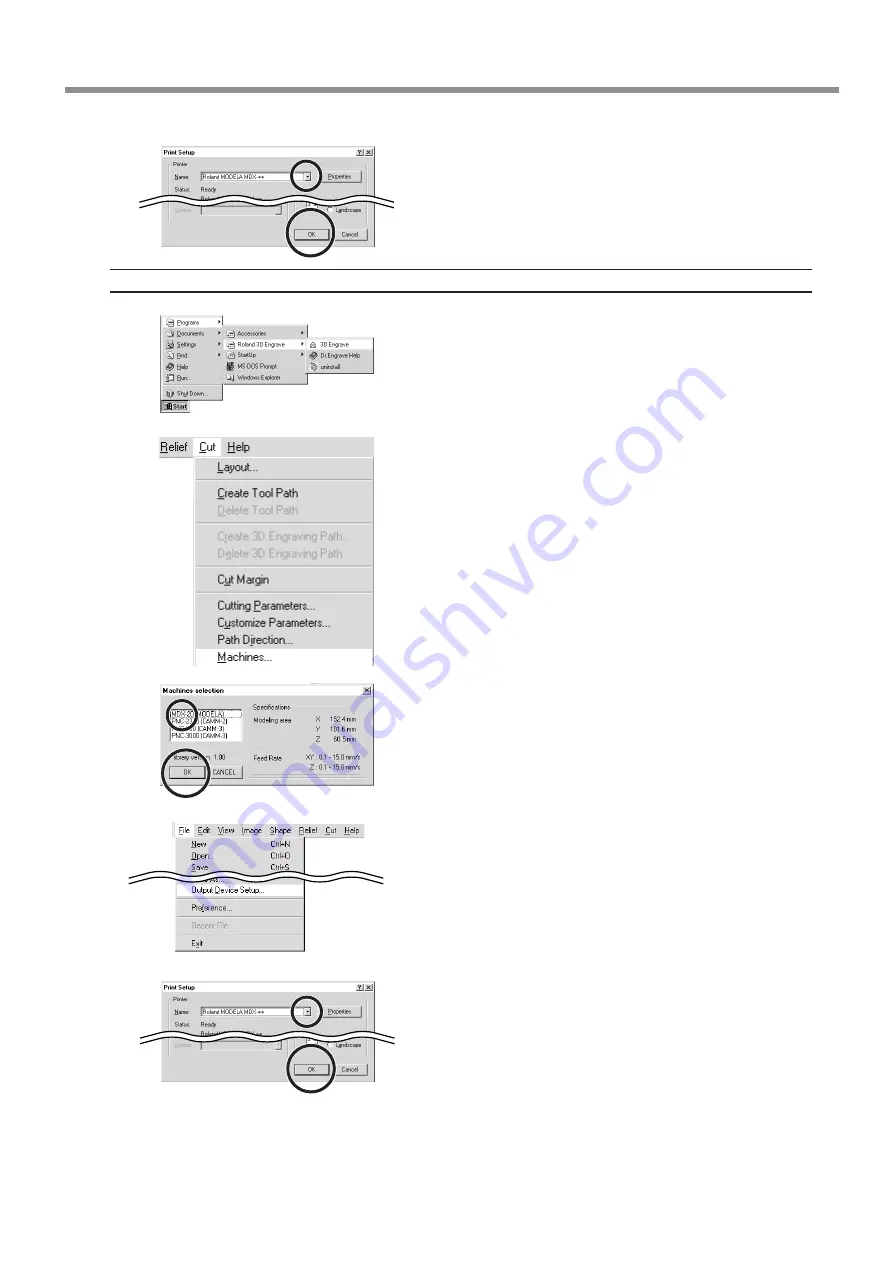

Click the drop-down arrow for the name and click [Roland

MODELA MDX-20]. Then click [OK].

3D Engrave

Click [Start].

Point to [Roland 3D Engrave] and click [3D Engrave].

From the [Cut] menu, click [Machines...].

The [Model Selection] dialog box appears.

Click [MDX-20], then click [OK].

From the [File] menu, click [Output Device Setup].

The [Print Setup] dialog box appears.

Click the drop-down arrow for the name and click [Roland

MODELA MDX-20].

Then click [OK].