Setting Up and Connection

Setting

NOTICE

Never install this unit in any of the following situations, as it could result in damage:

• Places where the installation surface is unstable or not level.

• Places with excessive electrical noise.

• Places with excessive humidity or dust.

• The EGX-20 generates heat when used, and should not be installed in an area with poor heat radiation characteristics.

• Places with excessive vibration.

Use within a temperature range of 5 to 40°C (41 to 104°F) and within a humidity range of 35 to 80%.

Securely connect the power cord, computer I/O cable and so on so that they will not be unplugged and cause

failure during operation. Doing so may lead to faulty operation or breakdown.

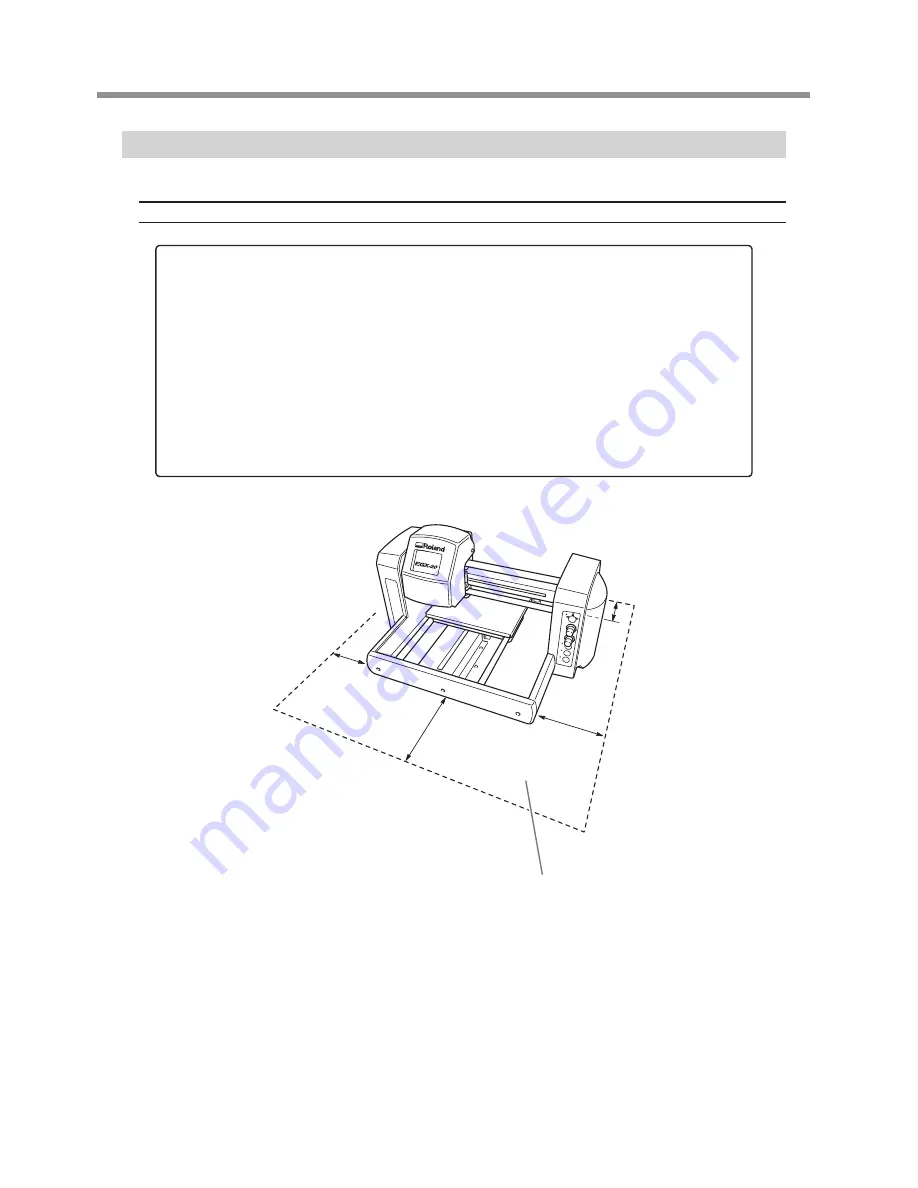

* Do not place any object within the area

10 cm (4 in.)

10 cm (4 in.)

30 cm (12 in.)

30 cm (12 in.)

8

1 Getting Ready

Summary of Contents for EGX-20

Page 51: ......