Rockwell Automation Publication 520-UM001K-EN-E - August 2021

163

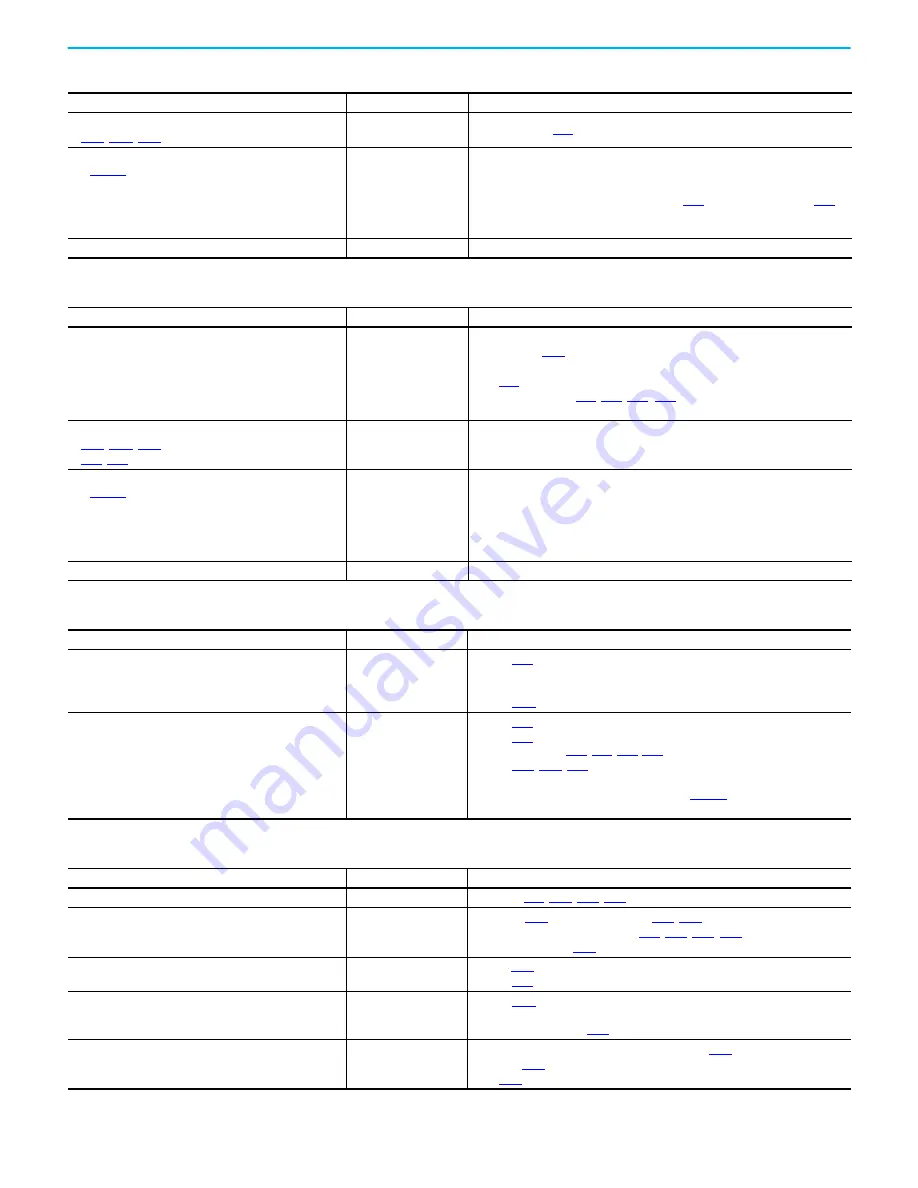

Chapter 4 Troubleshooting

Incorrect programming.

•

[Start Source x] is set incorrectly.

None

Check setting for

[Control Source].

Incorrect input wiring.

See

for wiring examples.

• 2 wire control requires Run Forward, Run Reverse or Jog

input.

• 3 wire control requires Start and Stop inputs

• Stop input is always required.

None

• Wire inputs correctly and/or install jumper.

• If the PowerFlex 525 Safe Torque Off function is used, verify that inputs are active.

• If 2-wire or 3-wire mode is used, verify that

[DigIn TermBlk 03] are set properly.

Incorrect sink/source jumper setting.

None

Set switch to match wiring scheme.

Motor does not Start (Continued)

Cause(s) (Continued)

Indication

Corrective Action

Drive does not Start from Start or Run Inputs wired to the terminal block

Cause(s)

Indication

Corrective Action

Drive is Faulted

Flashing red status light

Clear fault.

• Press Stop if

[Stop Mode] is set to a value between “0” and “3”.

• Cycle drive power.

• Set

[Fault Clear] to 1 “Reset Fault” or 2 “Clear Buffer”.

• Cycle digital input if

[DigIn TermBlk xx] is set to

13 “Clear Fault”.

Incorrect programming.

•

[Start Source x] is set incorrectly.

•

[DigIn TermBlk 02/03] is set incorrectly.

None

Check parameter settings.

Incorrect input wiring.

See

for wiring examples.

• 2 wire control requires Run Forward, Run Reverse or Jog

input.

• 3 wire control requires Start and Stop inputs

• Stop input is always required.

None

• Wire inputs correctly and/or install jumper.

• If the PowerFlex 525 Safe Torque Off function is used, verify that inputs are active.

Incorrect sink/source jumper setting.

None

Set switch to match wiring scheme.

Drive does not respond to changes in speed command

Cause(s)

Indication

Corrective Action

No value is coming from the source of the command.

The drive “Run” indicator

is lit and output is 0 Hz.

[Control Source] for correct source.

• If the source is an analog input, check wiring and use a meter to check for presence

of signal.

[Commanded Freq] to verify correct command.

Incorrect reference source is being selected by remote

device or digital inputs.

None

[Control Source] for correct source.

[Dig In Status] to see if inputs are selecting an alternate source.

,

[DigIn TermBlk xx].

[Speed Referencex] for the source of the speed

reference. Reprogram as necessary.

• Review the Speed Reference Control chart on

• Verify communications if used.

Motor and/or drive will not accelerate to commanded speed

Cause(s)

Indication

Corrective Action

Acceleration time is excessive.

None

[Accel Time x].

Excess load or short acceleration times force the drive into

current limit, slowing or stopping acceleration.

None

• Compare

[Output Current] with

[Current Limit x].

• Remove excess load or reprogram

,

• Check for improper

Speed command source or value is not as expected.

None

• Verify

[Commanded Freq].

[Control Source] for the proper Speed Command.

Programming is preventing the drive output from

exceeding limiting values.

None

[Maximum Freq] to ensure that speed is not limited by

programming.

[Speed Ratio].

Torque performance does not match motor characteristics. None

• Set motor nameplate full load amps in parameter

[Motor NP FLA].

• Perform

[Autotune] “Static Tune” or “Rotate Tune” procedure.

• Set

[Torque Perf Mode] to 0 “V/Hz”.

Summary of Contents for Allen-Bradley PowerFlex 520 Series

Page 8: ...8 Rockwell Automation Publication 520 UM001K EN E August 2021 Table of Contents Notes ...

Page 68: ...68 Rockwell Automation Publication 520 UM001K EN E August 2021 Chapter 2 Start Up Notes ...

Page 236: ...236 Rockwell Automation Publication 520 UM001K EN E August 2021 Appendix F PID Set Up Notes ...

Page 270: ...270 Rockwell Automation Publication 520 UM001K EN E August 2021 Index Notes ...