16

Pub. 1147 - Rev. 7 SEPTEMBER 2004

Mechanical Dock Leveler Hydraulic Conversion

CUT AWAY ALL MECHANICAL HARDWARE

1. Relieve tension on all springs and hardware. With

all loads removed, torch away all mechanical parts

from the leveler that move the platform or the lip.

Parts that typically need to be cutaway are

Hydracheck

®

brackets, lifter cams, lip lugs, lifter arm

supports, and safety legs. Grind necessary areas to

eliminate appearance concerns and allow for a

smooth surface for conversion kit to be mounted.

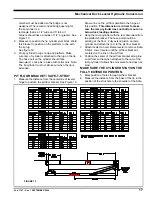

RAMP PLATFORM BRACKET PLACEMENT

(CENTER CHANNEL MUST BE LOCALLY

REMOVED FOR SERCO LEVELERS)

1. Measure from the rear hinge to position the ramp

platform clevis bracket. See figure 12 for

dimensions.

2. Trim the length of the center bracket assembly to

match the dimension from outside of stringer to

outside of stringer on the center bay.

3. Tack weld the bracket in place to the stringers. The

bracket should open toward the front of the leveler .

Insure the bracket is square to the leveler deck so

the hydraulic cylinder stays on the center line of the

leveler..

4. Cut the 3/8” thick flat plate to fit (vertical) between

the stringers and match the stringer shape as

closely as possible.

5. Tack weld the flat plate in place tightly against the

rear side of the first bracket and perpendicular to the

stingers.

6. Recheck dimensions to Figure 12.

7. Weld securely in place to the stringers and weld the

brackets securely together.

8. It may be necessary to cut a hole in one stringer to

install the pin into the cylinder.

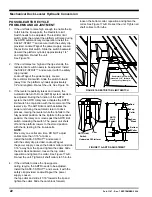

LIP CYLINDER AND BRACKETS

1. Measure to position the lip cylinder lug. See figure

12 for dimensions. Weld this lug in position on the lip

next to the spool. It may be necessary to install a

bridge in the header for the lip cylinder. If a bridge

is already present, center lip cylinder lug on bridge

opening. If the bridge must be cut, a reinforcing

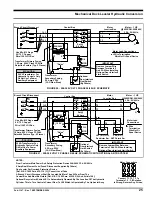

FIGURE 10 (CHAIN INSTALLATION)

12.00 REF.

Chain Assy.

FIGURE 11 (DECAL INSTALLATION)