Pub. 1147 - Rev. 7 SEPTEMBER 2004

19

Mechanical Dock Leveler Hydraulic Conversion

ELECTRICAL WIRING

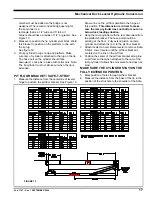

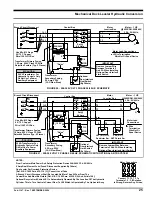

1. Connect electrical wiring per Figures 18-27

.

Be

sure to use the correct wiring diagram for the power

provided and the pump assembly ordered.

2. Install the operation switch per Figure 2.

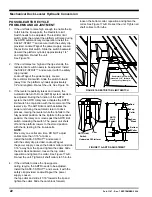

LIP KEEPERS

1. Using the hoist, slowly lower the leveler platform.

While lowering, make sure the stringers of the

leveler do not impact the pump assembly and other

parts. Also check that the ramp cylinder does not

bottom out.

2. With the leveler flush with the pit wall, mark the

position of the lip keepers on the front of the frame.

Place strut under leveler.

3. Weld lip keepers in place. See Figure 14B for

recommended lip keeper support for levelers with

inadequate front

subframes.

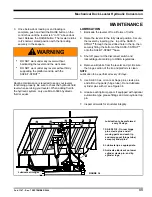

UNIT TEST

1. With the unit fully lowered, activate the power switch

to partially raise the leveler platform. Allow the

leveler to return itself to the lip keepers. Do this

several times to purge the air from the system.

2. Raise the leveler to the full open position and check

for leaks. If leaks do occur, place the leveler on the

Safe-T-Strut and repair leaks.

3. IMPORTANT: With the strut in place (through the lip

hole and on the strut base) test that the leveler does

not lift above the strut top or interfere with the

leveler operation in any way. If the strut does not

remain captured by the lip or if the strut binds in the

lip: consult Rite Hite for the correct strut application.

4. Refill hydraulic fluid tank to indicated level.

BRACKET ADJUSTMENTS

1. Lower leveler to below dock end load position. If

ramp cylinder bottoms out, adjust pit floor bracket

toward front of pit one set of holes.

2. Raise leveler to highest position. Insure toe guards

do not come out of pit.

3. Weld the ramp platform bracket securely in place.

This includes welding this bracket to its base and

the stringers of the platform.

4. Weld the movable portion of the pit floor bracket to

its base. Leave bolts in place.

5. Paint all brackets and welds to control rust.

PUMP ADJUSTMENTS

1. Run leveler and adjust properly

a. Adjust shuttle valve so that leveler platform

lowers from top to bottom in 14-16 seconds.

-Adjust the shuttle valve in 1/8-1/4 turn at a time

to speed platform decent

-Adjust the shuttle valve out 1/8-1/4 turn at a

time to slow platform decent

2. Lip control adjustment

a. Adjust the sequence valve

IN

1/4 turn at a time

to slow lip kick at the top of the cycle and stop

lip kick at below dock start up.

b. Adjust the sequence valve

OUT

1/4 turn at a

time to speed lip kick at the top of the cycle. Be

careful not to create a lip kick situation at a

below dock start up.

AUTOMATIC RETURN TO DOCK

(ARTD)

GENERAL

The ARTD limit switch assembly automatically turns the

hydraulic power unit on and off to recycle the leveler

from below dock level to dock level, provided the lip has

been fully extended. A recycle actuator with a rotary

cam assembly moves forward and backward with the

extension and retraction of the lip cylinder. The cylinder

rod moves forward (out) to extend the lip, and backward

(in) to retract the lip.

See Figure 17.

ARTD OPERATION

When the RAISE button is pressed and the ramp

cylinder has fully extended, the lip cylinder rod extends.

The roller of the ARTD limit switch contacts the cam

block, causing the cam to rotate into its “Cylinder

Extend” position. After the cam block passes beyond the

end of the roller plunger limit switch, the cam returns to

its “Cylinder Retract” position. When the lip lowers

toward the pendant position, the lip cylinder retracts,

moving the cam assembly backward. The cam block

contacts the roller of the limit switch, closing the switch.

The power unit is activated, raising the leveler. As soon

as the lip has lowered to the fully pendant position, the

cam block moves past the roller of the limit switch,

which opens the switch and stops the hydraulic power

unit. The leveler returns to the stored position with the

pendant lip lowering into the lip supports. See Figure 17.

The restrictor limit switch prevents the leveler from

raising too high. See Figure 16.