Pub. 1147 - Rev. 7 SEPTEMBER 2004

35

Mechanical Dock Leveler Hydraulic Conversion

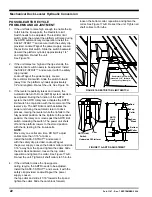

SEQUENCE VALVE ADJUSTMENT

(CONTROLS LIP EXTENSION)

NOTE

•

When making adjustments in extremely cold

temperatures (below freezing 32°F), run unit several

times (5 to 10 cycles) to confirm that the velocity

fuse does not lock-up with warmer oil.

•

Check oil level before making any

adjustments.

1. When the leveler is fully raised and the lip does not

extend, the Sequence Valve is set too high.

2. Remove protective cap and O-ring. Loosen locknut;

without turning valve body or adjustment screw.

Turn adjustment screw counterclockwise to lower the

valve pressure setting.

See Figure 36.

NOTE

Valve is factory set at 0.70". See Figure 36.

3. Adjustments should be no more than 1/8 turn

increments.

4. Tighten locknut without turning valve body or

adjustment screw.

5. Reinstall O-ring and protective cap and tighten cap.

6. Re-test the unit several times to verify the setting.

7. If the lip begins to extend at any time before the

platform has fully raised, the Sequence Valve setting

is too low.

8. Remove protective cap and O-ring. Loosen locknut;

without turning valve body or adjustment screw. Turn

adjustment screw clockwise to increase the valve

pressure setting.

9. Adjustments should be no more than 1/8 turn

increments.

10. Tighten locknut without turning valve body or

adjustment screw.

11. Reinstall O-ring and protective cap and tighten cap.

12. Re-test the unit several times to verify the setting.

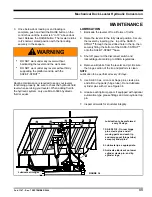

•

Do not operate leveler with anyone

standing on or in front of the lip.

•

Never go under the hydraulic leveler

unless power is locked out and tagged

out according to OSHA regulations and

approved local codes.

•

Sequence value is factory sealed.

Adjustments to be complete by trained

technician only.

DANGER

WARNING