Pub. 1147 - Rev. 7 SEPTEMBER 2004

33

Mechanical Dock Leveler Hydraulic Conversion

3

.

Once below dock loading or end loading is

complete, push and hold the RAISE button on the

control box until the leveler is 6” to 10” above dock

level. Release the RAISE button. The leveler returns

to it's normal, stored position with the lip resting

securely in the keepers.

Routine maintenance is required to keep your leveler

functioning properly. Be sure to check the hydraulic fluid

level when servicing your leveler. When adding fluid to

the hydraulic system, only use MIL-H-5606 hydraulic

fluid or equal.

LUBRICATION

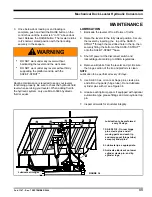

1. Barricade the leveler off to all forms of traffic.

2. Raise the leveler to the fully raised position. Secure

the leveler by inserting the top of the SAFE-T-

STRUT

TM

through the pre-drilled hole in the lip, then

securely fitting the bottom of the SAFE-T-STRUT

TM

onto the SAFE-T-STRUT

TM

base.

3. Shut off power at the disconnect switch and

lockout/tagout according to OSHA regulations.

4. Remove all debris from the leveler and pit. Be sure

the hinge section of the lip and platform is clean.

NOTE

Lubrication to be performed every 30 days.

5. Use SAE 30 wt. oil on rear hinge pins, clevis pins,

and all moving parts,(hinge tube). Do not lubricate

cylinder pins with oil. see Figure 34.

6. Grease each lip/ramp spool if equipped with optional

automotive type grease fittings and main cylinder top

pin.

7. Inspect all welds for structural integrity.

MAINTENANCE

FIGURE 34

Lubrication to be preformed

every 30 days.

1. SAE 30 Oil - On rear hinge

pins, clevis pins and all

moving parts and each lip

and ramp spool (hinge tube)

except cylinder pins.

2. Lubricate lip as appropriate.

3. Anti-seize lubricant on lower

cylinder clevis pin, and lip

cylinder lugs.

Lubricate all hinges

1

1

2

2

2

2

2

2

2

2

2

2

2

3

•

DO NOT work under any leveler without

barricading the leveler and the work area

•

DO NOT work under any leveler without firmly

supporting the platform and lip with the

SAFE-T-STRUT

TM

.

WARNING