Pub. 1147 - Rev. 7 SEPTEMBER 2004

17

Mechanical Dock Leveler Hydraulic Conversion

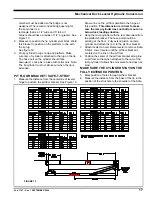

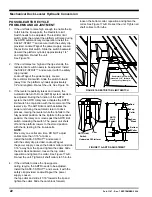

member must be added so the bridge is not

weakened. The recommended bridge opening for

the lip cylinder is a

rectangle that is 4-1/2” wide and 5” tall. All

corners should have a radius of 1/2” or greater. See

Figure 13.

2. Measure to position the lip cylinder pivot block. Weld

this bracket in position on the platform, in line with

the lip lug.

See figure 12

.

3. Pin lip cylinder to lugs on lip and platform. Make

sure ram of cylinder is attached to the lug on the lip.

The hose port on the cylinder should face

downward. Lock pins in place with cotter pins. Note:

The lip cylinder must not stroke out when the lip is

extended.

PIT FLOOR BRACKET / SAFE-T-STRUT

1. Measure the distance from the centerline of leveler

hinge to position the pit floor bracket. See Figure 12

.

Draw a line on the pit floor parallel to the hinge at

this position.

This dimension is critical to make

sure the ramp cylinder does not bottom out on a

below dock loading situation.

2. Hang the ramp cylinder with the ram downward from

the platform bracket. The hose port should be

pointing at the floor. Fully extend piston on ramp

cylinder and attach the ram to the pit floor bracket.

3. Attach leveler to hoist. Raise leveler to remove Safe-

T-Strut. Lower leveler until the pit floor bracket is

centered on the line on the pit floor.

4. Position the center of the pit floor bracket along line

on pit floor so that when attached to the ram of the

ramp cylinder it allows free movement and does not

bind.

MAKE SURE THE CYLINDER STAYS IN THE

FULLY EXTENDED POSITION.

5. Mark position of holes through pit floor bracket.

6. Measure the distance from the base of the lip in the

position of the strut hole to the shoulder of the Safe-

FIGURE 12