24

Pub. 1147 - Rev. 7 SEPTEMBER 2004

Mechanical Dock Leveler Hydraulic Conversion

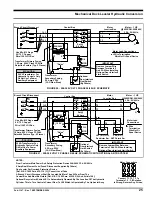

TYPE 1 CONTROLS

Branch Circuit

Disconnect

L1

L2

1L1

L2

1L1

L2

T1

T2

Thermal

Overload

G

G

See Electrical

Installation Details Below

60 / 75 C Copper

Wire/100 Ft. Of Run

20 Amp. Circuit 120V.

15 Amp. Circuit 240V.

Motor – 3/4 HP

2850/3450 RPM

120/240V 1 Ph. 50/60 Hz.

Intermittent Duty

(Thermally Protected

With Automatic Reset)

Pushbutton

Control Box

Type 1

Control Box

TYPE 2 CONTROLS

Branch Circuit

Disconnect

L1

L2

1L1

L2

Restrictor LS

T2

T1

T2

To DOK-LOK

®

Timer Or Controller

For DOK-LOK

®

ITC.

(Optional)

T1

Thermal

Overload

G

G

G

See Electrical

Installation Details Below

60 / 75 C Copper

Wire /100 Ft. Of Run

20 Amp. Circuit 120V.

15 Amp. Circuit 240V.

Motor – 3/4 HP

2850/3450 RPM

120/240V 1 Ph. 50/60 Hz.

Intermittent Duty

(Thermally Protected

With Automatic Reset)

L2

1L1

Optional

“Raise”

Raise

ARTD

SOLID-STATE

LEVELER

CONTROL

MODULE

Door

Jumper Is Standard.

Remove Jumper If

Optional Overhead Door

ITC/ITL Is Installed

Reset

ARTD LS

1

2

4

5

6

7

8

9

Overhead Door ITC/ITL

External Reset

Type 2

Control Box

NOTES:

From Customer Main Power And Safety Protection Device 120/240V 1 Ph. 50/60 Hz.

(Fused Disconnect Supplied By Others)

(Must Use Either Dual Element Fuse Or Inverse Time Circuit Breaker

At Branch Circuit Disconnect.)

One Leveler Per Overload Protection Device.

[Ref. N.E.C. 1999 Para. 430-110 (C) ] Consult Local Code.

A Branch Circuit Disconnect Shall Be Located No More Than 50 Feet From The

Control Box And Must Be Visible. [Ref. N.E.C. 1999 Para. 430-102 (A) And Article 100.]

P1 P2 T3 T8 T2 T4

T1

T2

T5

120

VAC

Motor Wiring

P1 P2 T3 T8 T2

T1

T2

240

VAC

T4 T5

WIRING DIAGRAMS AND SCHEMATICS

FIGURE 18 - TYPE 1 STANDARD ELECTRICAL SCHEMATIC

FIGURE 19 - TYPE 2 STANDARD ELECTRICAL SCHEMATIC