Part V Manual Operation

BECS-09 Singular-head Computerized Embroidery Machine 61

5.9 Backward Code Float

This operation is to move the frame backward to the last stop code in the

design quickly, so as to let the machine start embroidery from anywhere.

Operation:

When the machine stops under the embroidery confirmation

mode “

”, select the option “Backward Code Float” in the first screen of

manual operation menu, press the confirmation key“ ”, and then the

machine will float backward to the last stop code or color-changing code and

stop there.

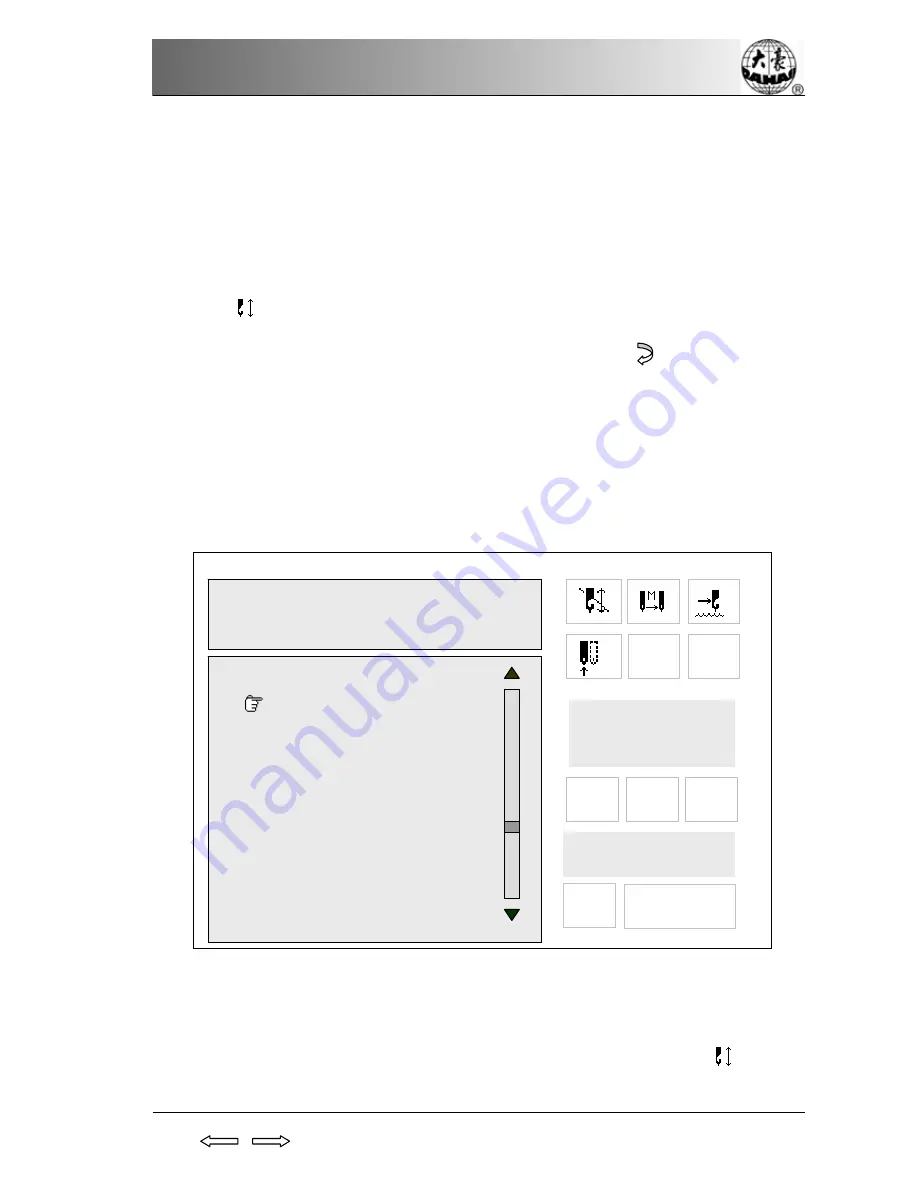

The second screen:

Enter the manual operation menu, and turn to the second

screen.

5.10 Forward Sti. Float

Operation:

In the main menu and under the embroidery confirm mode“

” , press

Forward Sti. Float

Backward Sti. Float

300

51

# 01

COL: 3

STI: 11791

P

F

X : + 123.5

Y : + 201.1

9

PD

PU