Service Menu

SM

4-15

M199/M200/M203/M204

S

yst

em

M

ai

n

te

n

an

ce

Ref

eren

ce

P

N

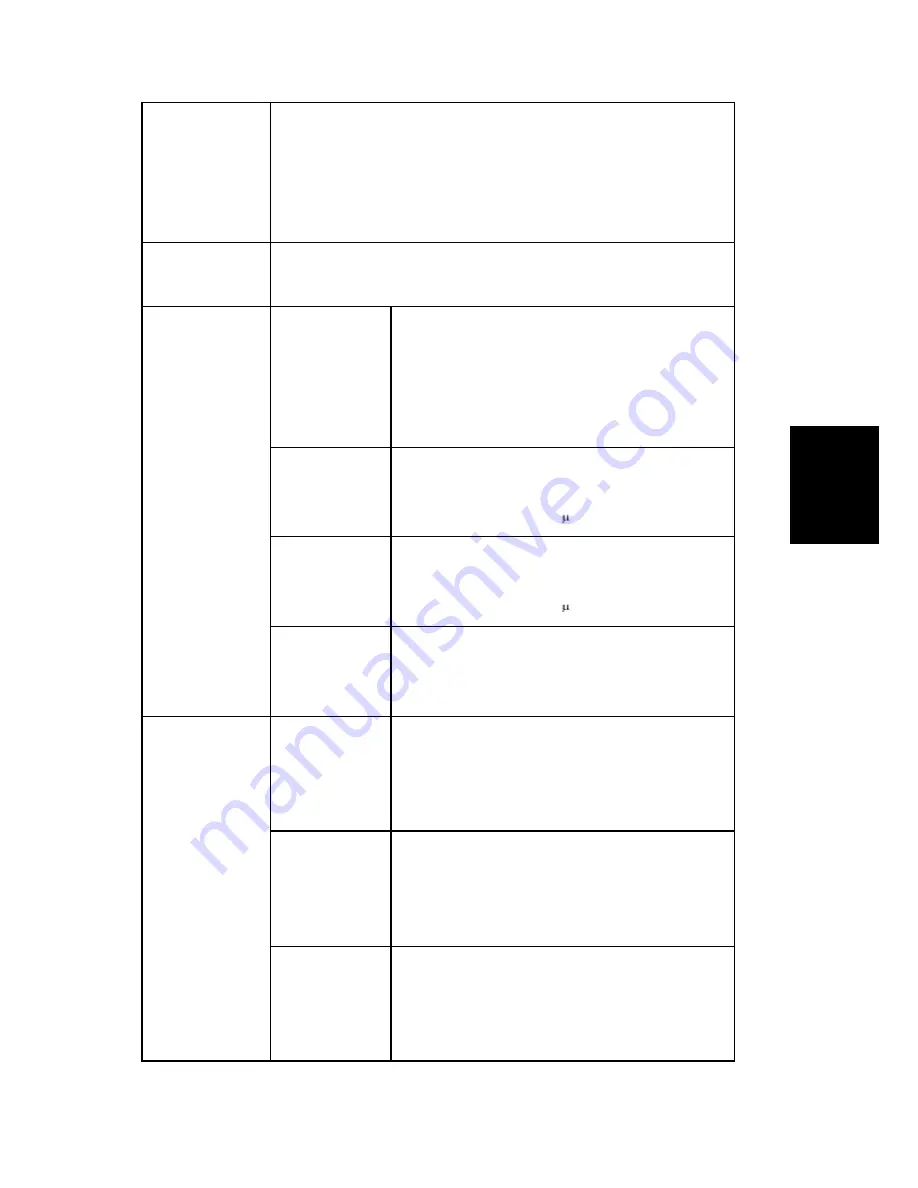

P Name

NA Model: RICOH/ 'nul'

EU Model: RICOH/ NRG/ LANIER

ASIA Model: RICOH/ LANIER

China Model: RICOH

[0x00 to 0x7F / - / -]

Destination

Sets the destination and updates the engine setting.

DOM/ NA (Default)/ EU/ CHN/ TAIWAN/ ASIA / LA

2nd Transfer

Media Type

Sets the Media type.

*Plain paper, Thin Paper, Thick Paper 2, Thick

Paper 1, Envelope, Cardstock, Bond Paper, Label

Paper, Prepunched, Preprinted, Letterhead, Color

Paper, Recycled Paper, Middle Thick

2nd Front

Adjusts the transfer roller current, based on the

default value.

[-15 to 15 / 0 (Default) / 1 A/step]

2nd Back

Adjusts the transfer roller current, based on the

default value.

[-15 to 15 / 0 (Default) / 1 A/step]

Fuser Temp.

Adjusts the temperature of the fusing unit, based

on the default value.

[-30 to 0 / 0 (Default) / 2°C/step]

Registration

Horiz. Tray1

Adjusts the horizontal registration for tray 1. If the

machine settings are reset to the factory defaults,

this value does not change.

[-15 to 15 / 0 (Default) / 1 mm/step]

Vert.Tray1

Adjusts the vertical registration for tray 1. If the

machine settings are reset to the factory defaults,

this value does not change.

[-15 to 15 / 0 (Default) / 1 mm/step]

Horiz Bypass

Tray

Adjusts the horizontal registration for the bypass

tray. If the machine settings are reset to the factory

defaults, this value does not change.

[-15 to 15 / 0 (Default) / 1 mm/step]

Summary of Contents for M199

Page 1: ...M199 M200 M203 M204 SERVICE MANUAL ...

Page 14: ...PRODUCT INFORMATION REVISION HISTORY Page Date Added Updated New None ...

Page 23: ...INSTALLATION ...

Page 27: ...REPLACEMENT AND ADJUSTMENT REVISION HISTORY Page Date Added Updated New None ...

Page 49: ...ADF only for MF Models M199 M200 M203 M204 3 22 SM 5 Document sensor C 4 hooks 1 ...

Page 68: ...Image Transfer SM 3 41 M199 M200 M203 M204 Replacement and Adjustment 7 ITB contact motor D 2 ...

Page 107: ...Electrical Components M199 M200 M203 M204 3 80 SM 7 PSU E 4 ...

Page 115: ...SYSTEM MAINTENANCE REFERENCE REVISION HISTORY Page Date Added Updated New None ...

Page 146: ...TROUBLESHOOTING REVISION HISTORY Page Date Added Updated New None ...

Page 174: ...ENVIRONMENTAL CONSERVATION REVISION HISTORY Page Date Added Updated New None ...

Page 180: ...M199 M200 M203 M204 SERVICE MANUAL APPENDICES ...

Page 182: ...APPENDIX SPECIFICATIONS REVISION HISTORY Page Date Added Updated New None ...

Page 200: ...APPENDICES PREVENTIVE MAINTENANCE REVISION HISTORY Page Date Added Updated New None ...

Page 207: ...PAPER FEED UNIT TK1010 G849 REVISION HISTORY Page Date Added Updated New None ...