SRP - User manual

Ref.: RX182/006

Version 01/2017 - English

This document must not be reproduced nor information therein disclosed without our authorization

Page 19 / 28

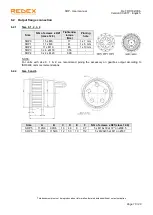

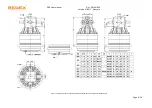

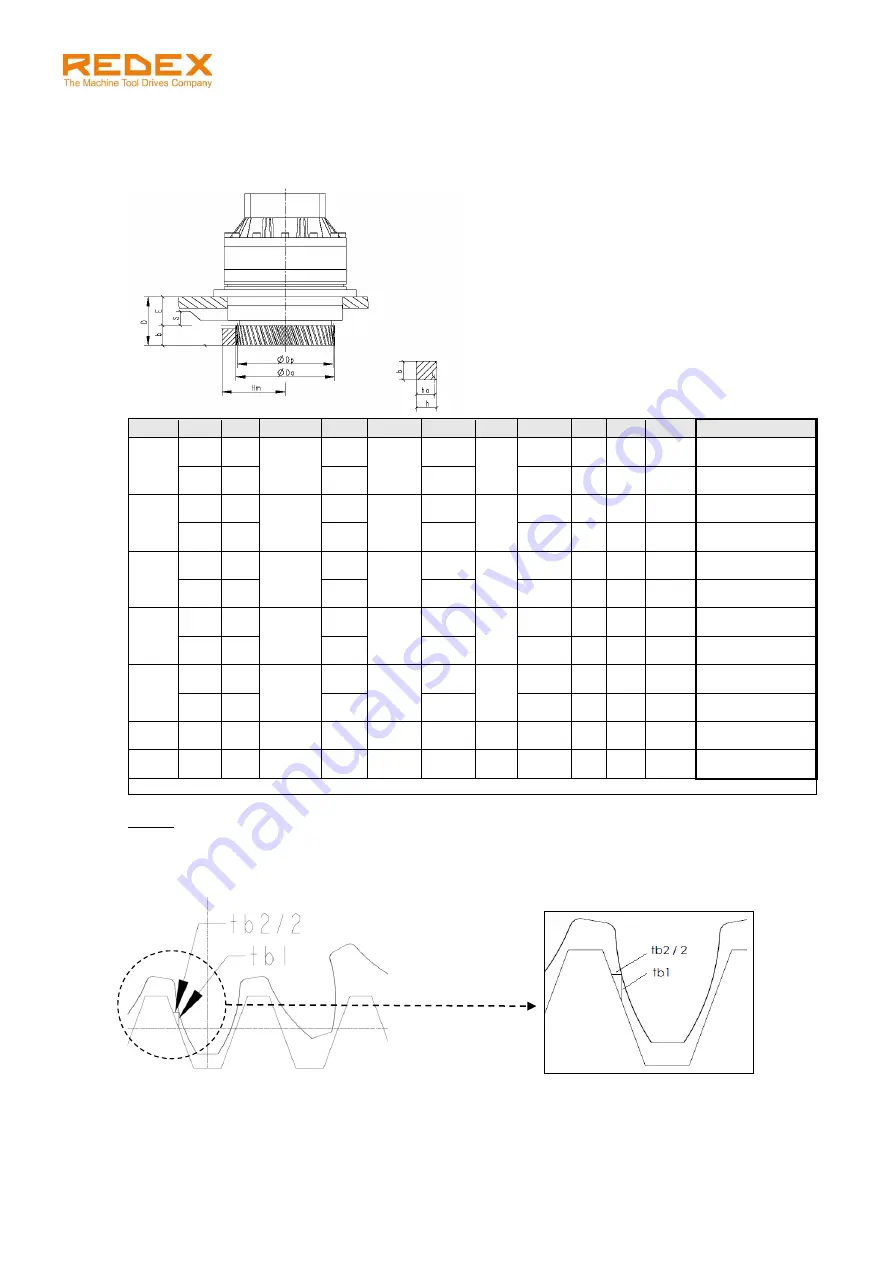

7.3 SRP mounting height setting

Determine and respect the mounting height of the SRP axis.

Respect the value hm that includes the tooth radial clearance tb

1

.

Size

Mo

Z

Dp

Da

E

D

S

tb

1

b

h

ho*

hm

0

2

45

95.49

100

29

59

6

0.075 30

24

22

70.075

+0.02

-0.02

2.5

36

101

29

0.1

30

24

21.5

69.6

+0.025

-0.025

1

2.5

42

111.41

117

38

68

6

0.1

30

24

21.5

77.6

+0.025

-0.025

3

35

118

73

0.1

35

29

26

82.1

+0.025

-0.025

2

3

52

165.52

173

50

85

8.5

0.1

35

29

26

109.6

+0.025

-0.025

4

39

175

95

0.15

45

39

35

118.65

+0.025

-0.025

3

4

45

190.99

201

66

111

12

0.15

45

39

35

131.65

+0.025

-0.025

5

36

203

121

0.2

55

39

34

130.7

+0.05

-0.05

4

5

42

222.82

236

75

130

15

0.2

55

39

34

147.2

+0.05

-0.05

6

35

238

141

0.2

66

49

43

156.2

+0.075

-0.075

5

8

15

127.32

147

99

178

9

0.3

79

79

71

137.8

+0.1

-0.1

6

10

14

148.54

177

126.5 225.5

11

0.4

99

99

89

168.9

+0.1

-0.1

* According to standard rack manufacturers (Güdel, Atlanta, etc…)

NOTE:

The machine frame supporting the unit must allow the adjustment of the distance centre hm.

The tooth radial clearance t

b1

(as well as the backlash between rack and pinion t

b2

, mentioned in the next

chapter) is detailed in the sketch below: