SRP - User manual

Ref.: RX182/006

Version 01/2017 - English

This document must not be reproduced nor information therein disclosed without our authorization

Page 12 / 28

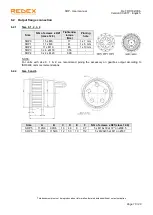

3. Check that the motor / gearbox interface dimensions are correct. Avoid the following improper

assemblies:

Motor shaft should

not reach the end of

the input bore.

Motor shoulder must

not reach the

clamping hub.

Motor radius must not

reach the clamping

hub.

Motor shaft must be

locked on the full

clamping hub width.

4. Make sure that the clamping screws of the input split-bore are not tight.

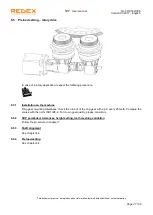

5. For size 6 only, install the 2 keys into the appropriate grooves to prevent the input bore from moving

down while mounting the motor. See pictures:

6. Lower the motor

vertically

onto the gearbox (and for size 6: maintain the 2 additional keys in

position) and fix it by tightening the 4 screws of the flange at the adequate tightening torque (table

below):

WARNING!

The motor must be mounted without applying any stress on the input shaft. The motor

centering is done by the gearbox input shaft. That is why it is absolutely necessary to mount

the motor vertically. A wrong mounting can lead to bad running conditions damageable for

the gearbox.

7. Gradually tighten the 2 clamping hub screws by half rotations until the tightening torque shown in the

table below is reached.

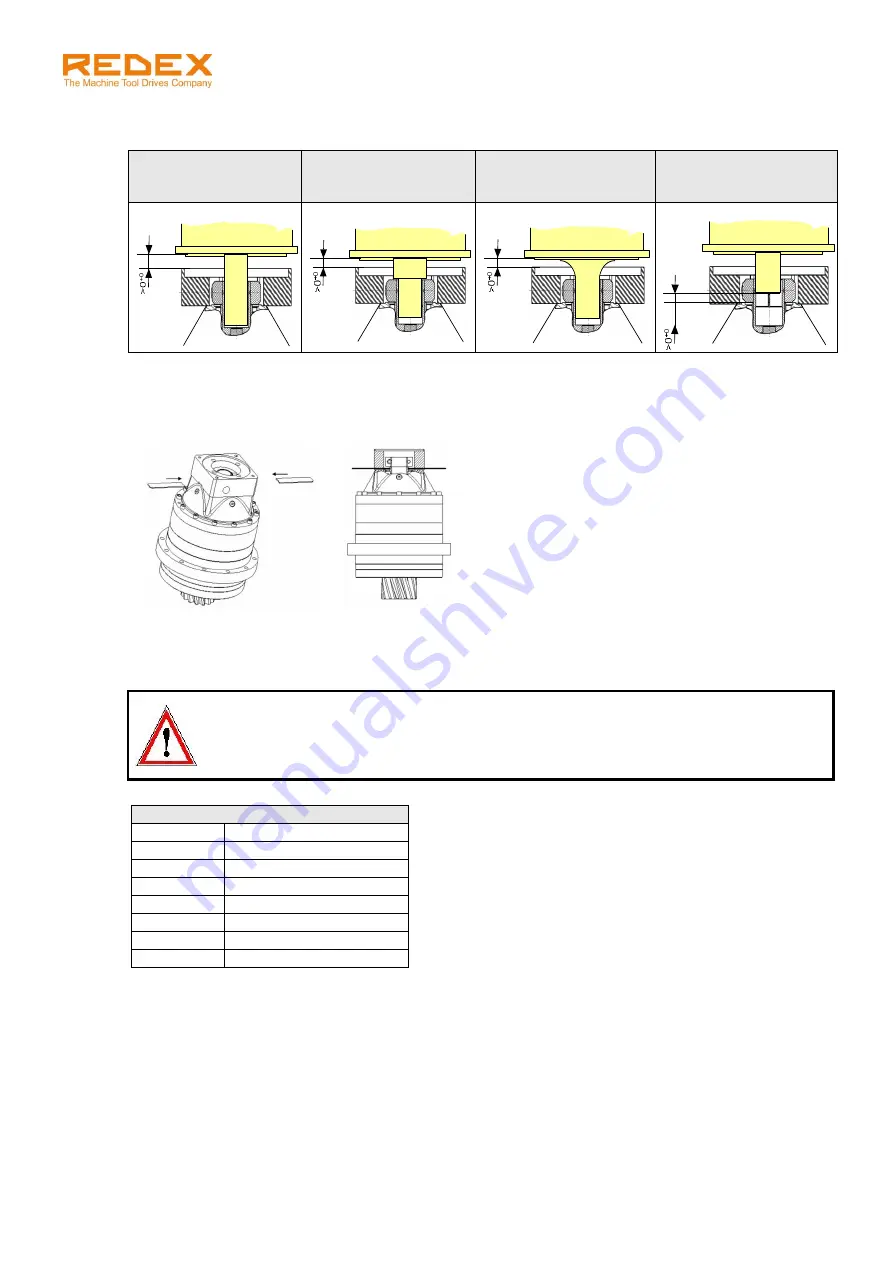

Screws of the motor flange

Screw type

Tightening torque (Nm)

M6

10

M8

25

M10

49

M12

86

M14

135

M16

210

M18

290