SRP - User manual

Ref.: RX182/006

Version 01/2017 - English

This document must not be reproduced nor information therein disclosed without our authorization

Page 17 / 28

7

MOUNTING OF THE SRP WITH OUTPUT PINION ON THE MACHINE

WARNING! HANDLING OPERATIONS.

The SRP unit can be handled by the main housing, the bevel box shafts, or, with lifting

rings by the output flange tapped holes.

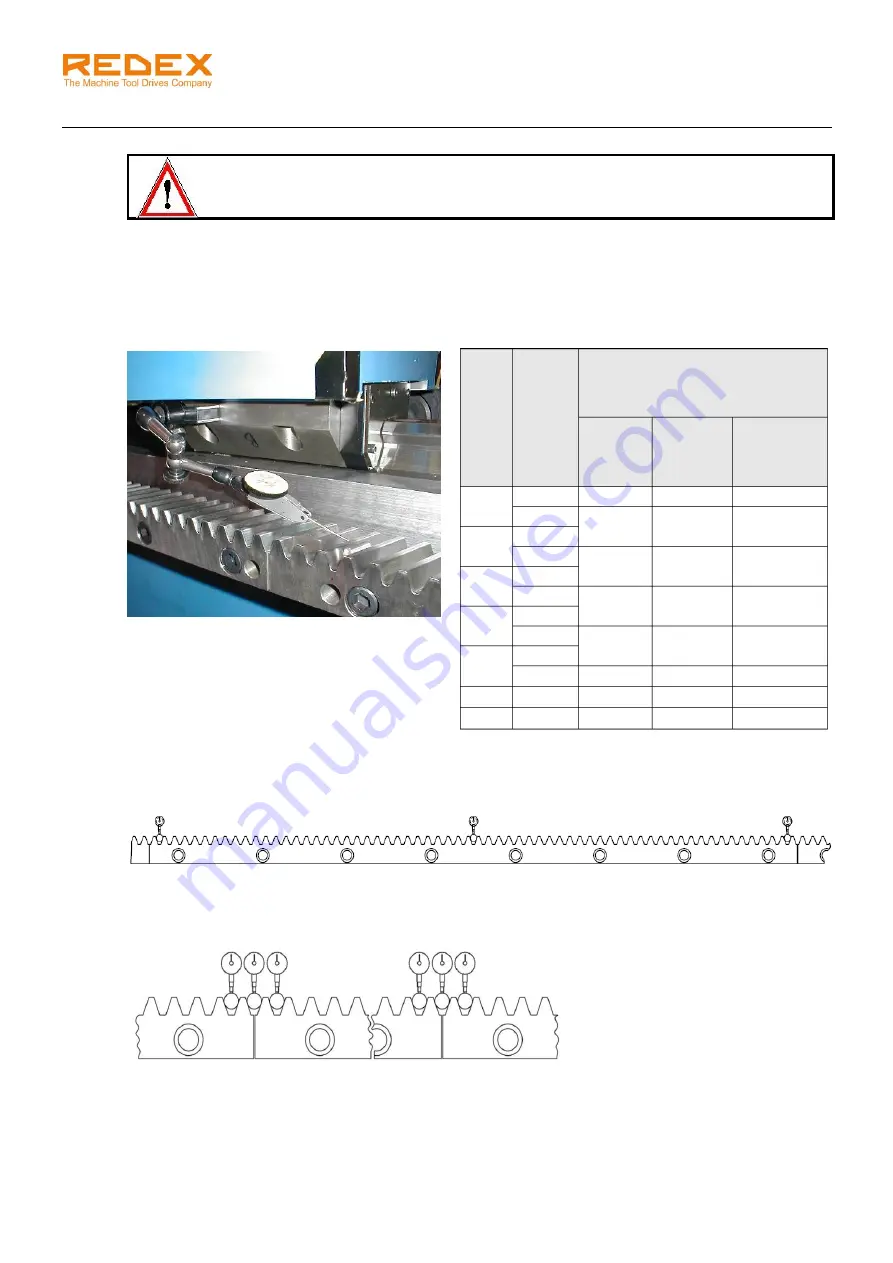

7.1 Rack mounting tolerance

Parallelism between the rack reference surface and the linear guide

The SRP requires that the rack has been installed on the machine following the rack manufacturer

mounting procedure and respects the tolerances shown below:

We advice to measure the parallelism error values on 3 points for each segment of rack, as shown on the

drawing below.

This rack topography will be used for proper tooth meshing validation and preload

setting (see next chapters).

In order to control the pitch error, we also recommend doing 3 measurements at each connection of 2

rack segments, as shown on the sketch below.

The variation between the 3 comparators at each connection must not exceed:

-

0.015 mm for a rack module 3,

-

0.020mm for a rack module > 3.

Size

Pinion

module

(mm)

Maximum parallelism error

between rack & linear guide

Pin

diameter

to use

For 1

section

of rack

(mm)

For

complete

axis length

(mm)

0

2

4

0,015

0,04

2,5

5

0,015

0,04

1

2,5

3

6

0,02

0,05

2

3

4

8

0,02

0,05

3

4

5

10

0,02

0,05

4

5

6

12

0,04

0,07

5

8

16

0,06

0,08

6

10

20

0,06

0,08