SRP - User manual

Ref.: RX182/006

Version 01/2017 - English

This document must not be reproduced nor information therein disclosed without our authorization

Page 20 / 28

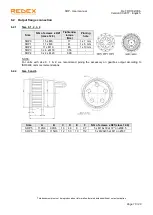

7.4 Proper tooth meshing validation

Checking that both pinions are properly meshing with the rack by measuring the clearance between rack

and pinion teeth (t

b2

)

1. Place two indicators as follow:

-

One between the SRP housing or carriage

and a fixed reference (1).

-

One between the SRP pinion (at pitch

diameter) and a fixed reference (2).

2. Move the carriage in one direction by turning the gearbox input shaft.

3.

Set the two indicators position at “0”.

4. Turn the input shaft to move the carriage in the other direction until both indicators have moved.

The difference between the measurements of the two indicators gives the backlash between rack &

pinion teeth (t

b2

). Compare the value with the values given in the table below.

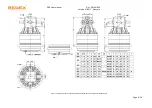

SIZE

Pinion

nbr of

teeth

Pinion

module

(mm)

t

b2

acceptable

backlash between

rack and pinion

0

45

2

0,050

0,015

mm

-0,015

36

2,5

0,070

0,015

mm

-0,015

1

42

2,5

0,070

0,015

mm

-0,015

35

3

0,070

0,015

mm

-0,015

2

52

3

0,070

0,015

mm

-0,015

39

4

0,1

0,015

mm

-0,015

3

45

4

0,1

0,015

mm

-0,015

36

5

0,135

0,035

mm

-0,035

4

42

5

0,135

0,035

mm

-0,035

35

6

0,135

0,05

mm

-0,05

5

15

8

0,205

0,070

mm

-0,070

6

14

10

0,275

0,070

mm

-0,070

In case of Dual- or Twin- arrangement (2 SRP), this operation should be done for both pinions

independently. It is also strongly recommended to repeat this operation at the highest and lowest points

of the rack topography (see chapter 7.1).

Explanation of t

b2

: