Supplied By www.heating spares.co Tel. 0161 620 6677

13

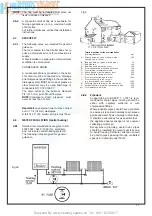

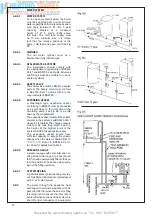

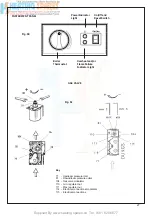

The sta

tic head available from the

cistern should be adequate to provide

the initial system design pressure.

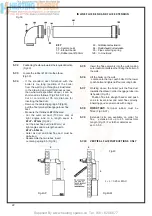

The cold feed pipe from the cistern should

include a non-return valve, and a stop-valve

with an automatic air vent connected be -

tween them, with the stop valve being locat-

ed, between the cistern and the automatic

air vent The stop valve may remain open

during normal operation of the system,

if automatic water make-up is required

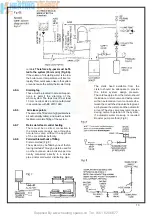

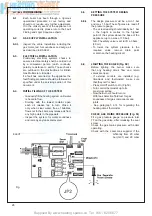

Booster pump method (Fig 8).

controls

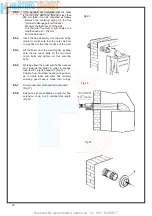

Therefore a by-pass must be fi t-

ted to the system (15 mm min) (Fig. 6A).

If the volume of circulating water is too low,

the boiler water temperature will rise too

rapidly This could cause noise in the system

or evene cause the safety thermostat to trip

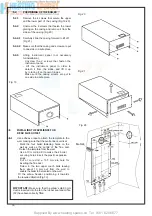

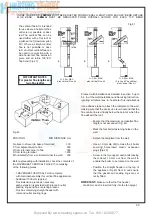

4.8.4. Draining

tap

These must be located in accessible posi-

tions to permit the draining of the

whole system The taps must be at least

15 mm nominal size and manufactured

in accor dance with BS 2870 1980.

4.8.5 Air

release points

These must be fi tted at all high points where

air will naturally collect, and must be sited to

facilitate complete fi tting of the system.

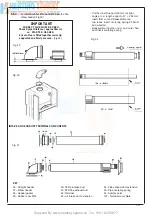

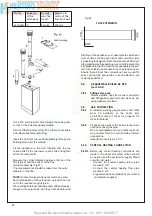

4.8.7 Mains

water

feed: central heating

There must be no direct connection to

the mains water supply, even through a

non- return valve, without the approval

of the Local Water Authority.

4.8.8

Permissible methods of fi lling

Cistern method (Fig 8)

The system may be fi lled by one of the fol-

lowing methods Through a cistern used for

no other purpose, via a ballvalve perma-

nently connected directly to a service

pipe and/or cold water distributing pipe .

Summary of Contents for HE Primary AAA

Page 16: ...Supplied By www heating spares co Tel 0161 620 6677 17 Fig 18...

Page 31: ...Supplied By www heating spares co Tel 0161 620 6677 Fig 58 32 Fig 56 Fig 57...

Page 33: ...Supplied By www heating spares co Tel 0161 620 6677 34 Fig 60 Fig 61 Fig 62 Fig 63...

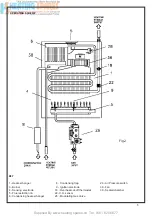

Page 42: ...Supplied By www heating spares co Tel 0161 620 6677 section 10 EXPLODED PARTS DIAGRAM 43...