Supplied By www.heating spares.co Tel. 0161 620 6677

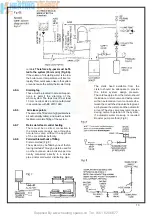

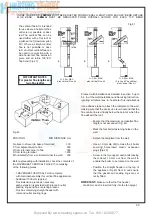

The system may be fi lled through a self

contained unit comprising of a cistern pres-

sure booster pump if required and if neces-

sary an automatic pressure reducing valve

or fl ow restrictor The cistern should be sup-

plied through a temporary connection from

a service pipe or cold water distributing

pipe The unit may remain permanently con-

nected to the heating system to provide lim-

ited automatic water make up

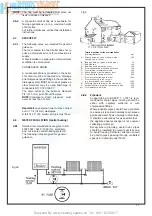

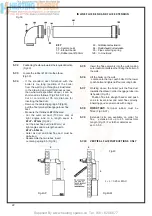

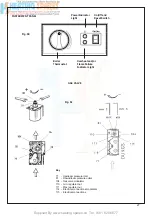

Mains topping up method (Fig 9)

Here the temporary connection is supplied

from a service pipe, or distributing pipe,

which also supplies other draw-off points at

a lower level

A combined double check valve shall be

installed upstream of the draw-off point,

through a temporary hose connection from

a tap supplied from the mains, where the

mains pressure is excessive a pressure

reducing valve shall be used to make fi lling

easier The following fi ttings shall form a

permanent part of the system and shall be

fi tted in the order stated

a) A stop valve complying with the require

ments of BS 1010 Part 2 (the temporary

hose from the draw off tap shall be con-

nected to this fi tting)

b) A test clock

c) Double check valve of an accepted

type

d) A non return valve of an accepted

type

We recommend use of a Ravenheat

Filling Loop

designed for this

method

of

fi lling the system Available

from your supplier

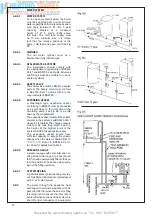

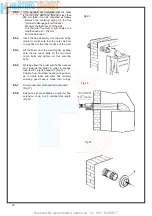

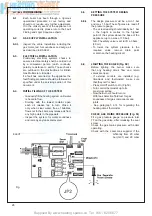

PROVISIONS FOR MAKE UP WATER

(Fig 7)

Provision can be made for replacing water

loss from the system either

A) from a manually fi lled made up bottle

with a readily visible water level The bottle

should be mounted at least 150 mm (6 in)

above the highest point of the system and

be connected through a non return valve

to the return side of the heating system

B) Where fi tting a make up vessel would

be diffi cult re pressurisation of the system

can be done See section on FILLING

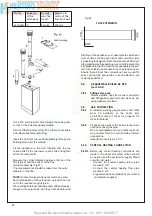

If the capacity of the central heating system

14

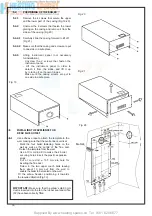

Safety

valve setting (bar)

30

Vessel charge

pressure (bar)

05

10

15

Initial system

pressure (bar)

05

10

15

20

10

15

20

15

20

Total water

content of system

EXPANSION VESSEL VOLUME (LITRES)

Litres

25

50

75

100

125

150

175

200

225

250

275

300

325

350

375

400

425

450

475

500

21

42

63

83

104

125

146

1 6 7

1 8 7

2 0 8

2 2 9

250

2 7 0

2 9 1

31 2

333

3 5 4

375

396

41 6

35

70

105

140

175

210

245

280

31 5

350

385

420

455

490

525

560

595

630

665

7 0 0

65

129

194

259

324

388

453

51 8

583

647

71 2

7 7 7

841

906

97 1

1036

1101

1165

1230

1259

137

275

413

551

689

826

964

1102

1240

1377

151 5

1653

179 1

1928

2066

2204

2392

2479

261 7

2755

27

54

82

109

136

163

191

218

245

272

300

327

357

38 1

409

436

463

490

51 8

545

47

95

142

190

237

285

332

380

427

475

52.2

570

61 7

665

71 2

7 6 0

807

855

902

950

103

206

309

412

515

618

721

824

927

1030

1133

1236

1339

1442

1545

1648

1751

1854

1957

2060

39

78

117

156

195

234

27 3

312

35 1

390

429

468

507

546

585

624

663

702

741

7 8 0

83

165

248

331

413

496

579

662

745

827

910

993

1076

1158

1241

1324

1407

1489

1572

1 6 5 5

For system volumes

other than those given

above, multiply the

system volume by

the factor across

00833

0 140

0 259

0 551

0 109

0 190

0 412

0 156

0 331

SIZING OF EXPANSION VESSEL TABLE 3

Note: This pressure can be increased up to 1.5 bar to suit high static head situations, see item 10, other appliance components in the

SERVICING INSTRUCTIONS

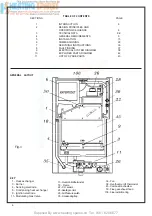

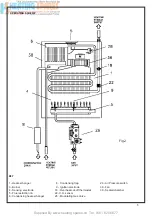

Summary of Contents for HE Primary AAA

Page 16: ...Supplied By www heating spares co Tel 0161 620 6677 17 Fig 18...

Page 31: ...Supplied By www heating spares co Tel 0161 620 6677 Fig 58 32 Fig 56 Fig 57...

Page 33: ...Supplied By www heating spares co Tel 0161 620 6677 34 Fig 60 Fig 61 Fig 62 Fig 63...

Page 42: ...Supplied By www heating spares co Tel 0161 620 6677 section 10 EXPLODED PARTS DIAGRAM 43...