Supplied By www.heating spares.co Tel. 0161 620 6677

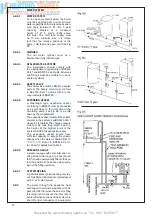

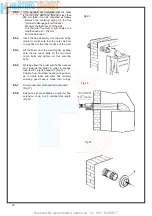

Fig. 48

26

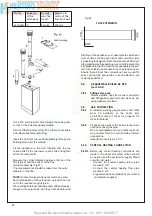

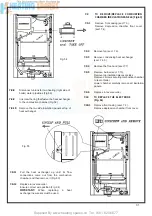

6.5

SETTING THE SYSTEM DESIGN

PRESSURE

6.5.1

The design pressure must be a min 1 bar

and max 1.5 bar These fi gures are read off

the pressure gauge.

- The actual reading should ideally be 1 bar

+ the height in metres to the highest

point of the system above the base of the

appliance (up to a max of 1,5 bar).

N.B. The safety valve is set to lift a 3 bars

(30 mt).

-

To lower the system pressure to the

required value remove drain point

or drain on the heating circuit.

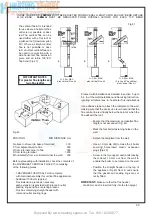

6.6

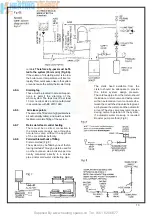

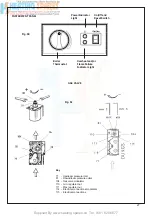

LIGHTING THE BOILER (Fig. 50)

Before lighting the burner make sure

that any heating circuit fl

ow and return

valves are open.

-

If external controls are installed (e.g.

timeclock and thermostat) make sure

that they call for heat.

- Press On/Off switch to On (Fig.50)

- Turn control thermostat up to its

maximum setting.

- Now the Burner should turn on

With leak detection fl uid test for gas

soundness of all gas components and

joints.

- See paragraph 6.14 for regulating the

heating circuit thermostat.

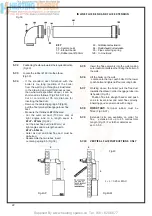

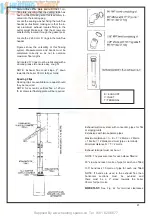

CHECK GAS MAINS PRESSURE (Fig. 51)

Fit a gas pressure gauge on pressure inlet

77 on the gas valve, after releasing the seal

screw.

Check the gas mains pressure with boiler

operating.

Check with the Local Gas supplier if the

pressure differs signifi cantly from 20 mbar

(natural gas), 37 mbar (G31) and 29 mbar

(G30).

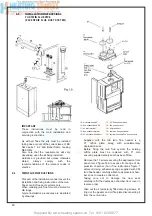

SECTION 6

COMMISSIONING

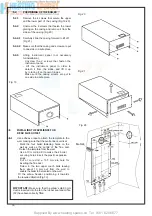

6.1

Each boiler has been through a rigorous

operational procedure at our factory and

should not require any further adjustment.

If in the unlikely event of the appliance not

operating correctly, please turn to the Fault

Finding and Logic Sequence charts.

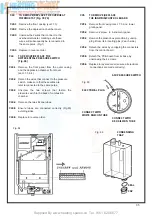

6.2

GAS SUPPLY INSTALLATION

6.2.1

Inspect the entire installation including the

gas meter, test for soundness and purge, all

as described in BS 6891

.

6.3 ELECTRICAL

INSTALLATION

Preliminary electrical systems checks to

ensure electrical safety shall be carried out

by a competent person (earth continuity,

polarity, resistance to earth). Those checks

are outlined in the «Instructions for British

Gas Multimeter» Booklet.

If a fault has occurred on the appliance the

fault fi nding procedure should be followed as

specifi ed under the servicing section of this

document.

6.4

INITIAL FILLING OF THE SYSTEM

-

Gradually

fi ll the heating system until water

is heard to fl ow.

- Starting with the lowest radiator open

each air release tap in turn. Close it

only when clear water, free of bubbles,

fl ows out In the same way release air from

any high points in the pipework.

- Inspect the system for water soundness

and remedy any leaks discovered.

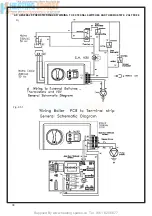

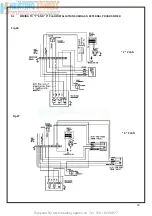

ELECTRICAL CONNECTION

Summary of Contents for HE Primary AAA

Page 16: ...Supplied By www heating spares co Tel 0161 620 6677 17 Fig 18...

Page 31: ...Supplied By www heating spares co Tel 0161 620 6677 Fig 58 32 Fig 56 Fig 57...

Page 33: ...Supplied By www heating spares co Tel 0161 620 6677 34 Fig 60 Fig 61 Fig 62 Fig 63...

Page 42: ...Supplied By www heating spares co Tel 0161 620 6677 section 10 EXPLODED PARTS DIAGRAM 43...