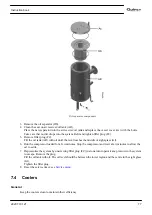

10.2 Heavy duty filter

Description

This system is equipped for "high efficiency" air filtration in order to improve the quality of the air intake and

to preserve the compressor's oil and internal filter components.

This option is particularly useful in very dusty surroundings.

Overview

• This option is used as a replacement for the standard filter

• The quality of the air intake by a compressor is essential. Low quality air creates the following :

• Quick pollution of the oil thus an increase in draining cycles.

• Binding of the air / oil separator before 4000 hours thus an increase in maintenance cycles and operation

costs.

• Pollution increases the elements that filter into the air and oil, speeding up the damage to the mechanical

components of the compressor, screw element, ...

• Installation of the filter(s), depending on the model, outside the compressor, for intake of fresh air, hence

resulting in a lower oil temperature and more efficient compression.

10.3 Pre-filtration panels

Description

Installing air filtration panels on the ventilation intakes guarantees protection of the compressor's internal

components and an increase in air sucked into the compression assembly.

This option is recommended if the heavy duty filtration option is installed

Overview

The pre-filtration panels eliminate 90% of the particles normally admitted inside the compressor and

considerably decrease internal contamination of the machine.

The high quality of the ventilation air is also essential for protecting internal components of the compressor

and, more specifically, the motor and the air / air and air / oil exchangers. Clogging in the exchangers creates

an increase in temperature, deterioration of the lubricant and the motor becomes overloaded thus increasing

the energy consumed.

Instruction book

2920 7101 21

91

Summary of Contents for QGS 40

Page 1: ...QGS 40 QGS 50 QGS 60 QGS 75 QGS 100 Instruction book Oil flooded rotary screw compressors...

Page 2: ......

Page 100: ......

Page 101: ......