Oil drain plugs

4. Collect the oil and deliver it to the local collection service. Refit and tighten the drain and vent plugs after

draining.

Re-tighten the top connection of the oil cooler.

5. Remove the oil filter (OF). Clean the seat on the manifold. Oil the gasket of the new filter and screw it

into place. Tighten firmly by hand.

6. Remove filler plug (FC).

Fill the air receiver/oil tank (AR) with oil until the level reaches the filler neck.

Take care that no dirt drops into the system. Refit and tighten filler plug (FC).

7. Run the compressor loaded for a few minutes. Stop the compressor and wait a few minutes to allow the

oil to settle.

8. Depressurise the system by unscrewing filler plug (FC) just one turn to permit any pressure in the system

to escape. Remove the plug.

Add oil, the oil level should be between the lower region and the centre in the sight glass (Gl).

Tighten the filler plug.

9. Reset the service warning after carrying out all service actions in the relevant Service Plan: see

.

7.3

Oil separator change

Warning

The operator must apply all relevant

.

Procedure

1. Run the compressor until warm. Stop the compressor, close the air outlet valve and switch off the voltage.

Wait a few minutes and depressurise by unscrewing oil filler plug (FC) just one turn to permit any pressure

in the system to escape.

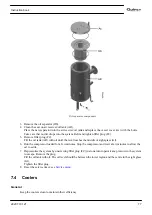

2. Remove the cover (Ac) from the air receiver/oil tank (AR) by unscrewing the bolts.

Instruction book

76

2920 7101 21

Summary of Contents for QGS 40

Page 1: ...QGS 40 QGS 50 QGS 60 QGS 75 QGS 100 Instruction book Oil flooded rotary screw compressors...

Page 2: ......

Page 100: ......

Page 101: ......